Society

Basic stance and policy

Safety and health first

As a global company, a critical management issue for us that strictly applies at every one of our locations is the building and maintenance of a workplace where everyone can perform safely and healthily.

Aisin has established the Aisin Group Safety and Health Policy and the Aisin Group Health Declaration based on the principle of “Safety and health first”, which applies at all times. We conduct various activities based on these policies and declarations.

Promotion Structure

Safety and fire-prevention Promotion Structure

To protect all individuals working on Aisin premises from work-related accidents, we have established a Safety and Health Committee composed of presidents from each Group company. This committee promotes activities aimed at unifying policies and standards. Matters discussed are reported to and approved by the Committee at each workplace and then progressively rolled out to individual workplaces via workplace safety promotion committee members. Furthermore, initiatives are disseminated to Group companies through the Aisin Group Safety and Health Study Group, while also providing support for safety activities tailored to each company's specific needs.

Strategy

Group Safety Vision for 2030

We work strenuously to prevent the recurrence of unfortunate incidents and eliminate catastrophic disruptions and lost-time injuries by applying strategies that enhance safety awareness and make safe behavior a habit.

We have established KPIs within the Group Safety Vision for 2030 and are working to create an environment where employees can work with peace of mind, remain physically and mentally healthy, and thrive.

As a point of ESG materiality and an element of solid management foundation, we have set a KGI of building a safety-first culture and committed to achieving zero major disasters as our benchmark for success.

Related materiality issues

| Materiality issues | Goals (KGI) | Indicators (KPIs) | FY2031 targets |

|---|---|---|---|

| Laying a solid management foundation | A culture that prioritizes safety | Zero serious accidents* | Zero serious accidents |

Serious accident defined as those involving fatalities

Key initiatives

Establishing a culture that prioritizes safety

Occupational Health and Safety Management System

To support risk management and raise performance, since FY2021, we have operated an Occupational Health and Safety Management System across the entire Aisin Group, including on-site contractors.

By FY2025, 39 Group companies, including the parent, have been certified for ISO 45001, an international standard. We annually assess risks and opportunities based on internal and external objectives and the needs of employees and other stakeholders. We prioritize the selected items, incorporate them into the following fiscal year's health and safety plan, and promote activities to achieve our goals. Based on the outcomes of our activities as well as other variables, management reviews are conducted. After clarifying our direction for the upcoming fiscal year, efforts are made to enhance the level of our initiatives.

ISO 45001 certification status (End-March 2025)

ISO 45001 acquisition rate*: 30%

OSHMS internal implementation: 50%

Applies to manufacturing companies

Other initiatives

Safety

Avoiding workplace accidents and preventing recurrence

Guided by the basic principle that safety and health take precedence over all else, we are committed to avoiding workplace accidents and preventing their recurrence. This we achieve by deepening safety awareness through on-site safety inspections and risk assessments targeted at infrastructure and operations. Group company leaders elicit information from the front line and work closely with employees to advance safety measure geared toward achieving a record of zero accidents. In the interest of a safe and healthy working environment, we prioritize safety and health above all else and will continue to rigorously and effectively promote safety.

AISIN Group meeting to prevent the recurrence of specific accidents

When a mishap occurs that shows the potential to escalate into a serious accident (STOP6 accident), AISIN and its Group companies convene a groupwide meeting to prevent similar accidents from occurring. To achieve this, the company where the accident occurred verifies and discusses the incident on-site (plant and department), after which it thoroughly investigates the cause and implements countermeasures.

Through these activities, we are shoring up our safety mechanisms to fully prevent serious accidents within our Group.

Worker lost-time injury frequency (employees at 12 Group companies)

STOP6 lost-time injury count (Aisin Group)

Aisin Global Safety Standard (AIGSS)

Based on international standards and lessons learned from past accidents, Aisin has established the Aisin Global Safety Standard (AIGSS) as the equipment safety standards the company must uphold. Using this standard, the Process Design Department, Manufacturing Department, and Safety Department identify equipment risks and implement countermeasures to promote the creation of safe and secure equipment and work practices.

Safety awareness activities

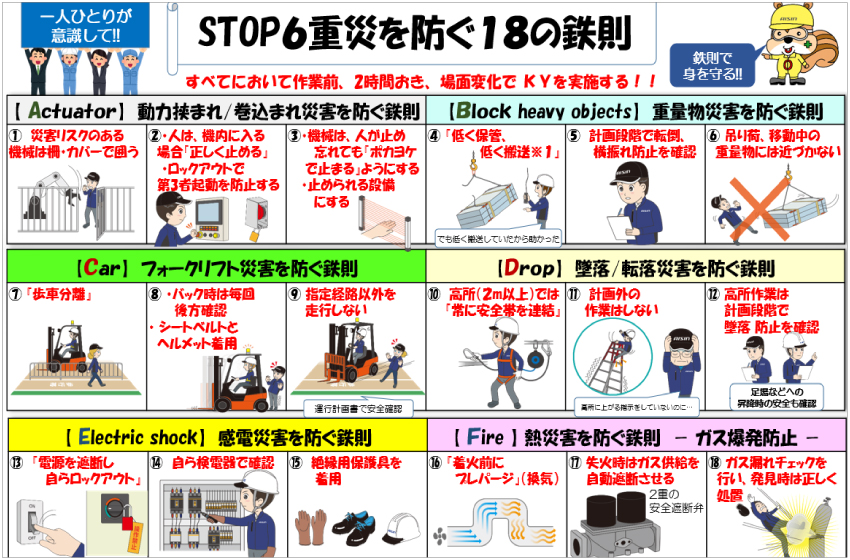

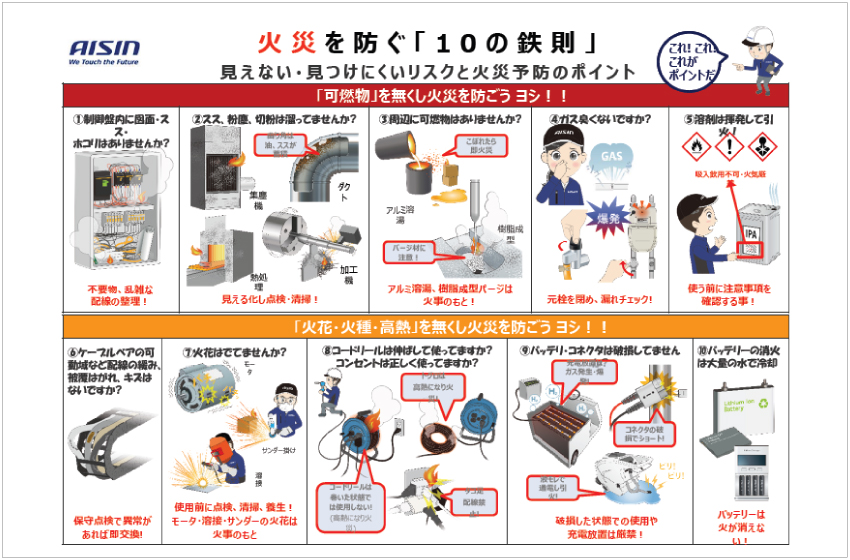

We have introduced 18 Iron Rules for Preventing STOP6 Accidents to strengthen our accident prevention effort by applying lessons from past incidents.

Based on experience gained from prior accidents, we promote measures to deepen understanding of the 18 Iron Rules for Preventing STOP6 Accidents across the entire group. By encouraging each employee to maintain regular awareness and to be alert for abnormalities under the fundamental Iron Rules, we raise safety awareness and prevent accidents.

Safety training

Aisin has established a Safety and Sanitation Education Center for educating our staff. It promotes 21 classes of workplace education (specialist and internal training) based on laws, regulations, and AIGSS*, including skills training programs approved by regional labor bureaus and national qualifying examinations. We aim to provide high-quality safety training and efficiently cultivate personnel qualifications to enhance employee skills and ensure safety.

Training center attendance

The spread of COVID-19 reduced class sizes and led to the postponement or cancellation of training events due to emergency declarations and other causes.

Held as scheduled while maintaining COVID-19 suppression measures

AISIN Densho-kan (education center)

Driven by the desire to ensure past events are not forgotten and prevent the recurrence of failures, the Group established the AISIN Densho-kan to share lessons learned from past accidents and fires affecting the company.

In the safety arena, we emphasize the need for visitor safety. By applying our core principles and accident timeline data and other statistics, we detail the causes and consequences of disasters through case study panels and animated features. Our fire prevention program focuses on ensuring that the Kariya Plant fire of February 1, 1997, is never forgotten. It presents imagery of actual equipment from the time of the incident and exhibits lessons learned. By making the horror of accidents and fires tangible and keeping memories of these events alive, we aim to heighten safety awareness and enable our personnel to protect themselves and their colleagues.

Safety instructors

Aisin has introduced a safety instructor system to implement safety guidance based on the principles of genchi, genbutsu, gennin, or a focus on actual sites and infrastructure and direct confirmation. Safety Instructors, trained as “guardians” with special safety promotion expertise through a 107-hour, 35-course program, support the promotion and management of safety across all workplaces within our facilities. The instructors work closely with employees in the field to neutralize potential hazards early and prevent accidents before they occur.

In the execution of their duties, our safety instructors promote activities to eradicate unsafe conditions and actions and, thereby, insulate their colleagues as well as their families and loved ones from potential grief.

Safety instructor program participants

Safety and fire prevention activities for construction contractors

We are committed to creating a safe and secure working environment for contractors operating within Aisin facilities.

(1) AISIN Group seminars on a safe environment for construction work by external contractors

We hold training sessions for external contractors and external work order issuers focusing on safety, environmental considerations, and fire prevention. Sessions are scheduled before seasonal holidays in spring, summer, and winter.。

(2) Step-Up Training & Safety Inspections

Aisin has introduced step-up training, a program for construction supervisors that was implemented since 2011 and upgraded to a formal requirement in 2019.

This training promotes construction safety management and the prevention of workplace accidents. Participants are instructed in regulations and management documentation to improve their ability to identify the causes of potential accident in advance and implement countermeasures. Participants learn concrete, practical methodologies covering planning and preventative measures, thereby promoting a safe and secure construction worksite. Additionally, we work jointly with external organizations to monitor the safety of construction sites where external contractors work and operations occurring there.

Participants completing step-up training

Safety and environmental activities for contractors, suppliers, and transport companies

In reflection of a serious incident that occurred in July 2015, we are committed to providing a safe, secure, and accident-free workplace.

(1) Safety information exchanges for on-site loading and unloading and subcontract work

We hold information exchange meetings twice a year (June and November) for workers involved with loading, unloading, and other contract work, as well as employees responsible for ordering such work.

(2) Other efforts at improvement

We work to improve difficult or hazardous conditions affecting our business and strive to create a safe work environment.

Industrial hygiene

Occupational health framework enhancement and prevention of health issues

Aisin aims to create a workplace where every employee can work energetically and be healthy. We are reorganizing systems and developing our staff to support sustainable occupational health management systems at each facility of our facilities. These efforts include the proactive management of chemical substances at the worksite.

To advance occupational health, we establish rules and standards, implement and provide training for clear methodologies for management and operations, and work to protect on site staff from occupational afflictions.

Specifically, to prevent health hazards before they occur, we properly manage harmful substances like organic solvents and dust, measure workplace discomfort factors such as heat stress and noise, and institute improvements based on the results to promote a more comfortable work environment.

Hazardous substances

Workplace noise

Control class I: equivalent sound pressure of below 85 dB equivalent

Control class II: equivalent sound pressure of 85 dB or above but below 90 dB equivalent

Control class III: equivalent sound pressure of 90 dB or above equivalent

“Primary Causes of Exceeding Standards”

Management Category II

- Hammering sounds, press operation sounds, etc.

Category III

- Air blowers, workpiece drop sounds, etc.

“Preventive Measures”

- Implement management based on internal standards for workers in Categories II and III, including earplug use and special health examinations

- Equipment countermeasures are being implemented sequentially according to plan

Management Category Evaluation [Measurement Results]

Organic Solvents

| Ⅰ | Ⅱ | Ⅲ | |

|---|---|---|---|

| Number of workplaces | 173 | 0 | 0 |

Particulates

| Ⅰ | Ⅱ | Ⅲ | |

|---|---|---|---|

| Number of workplaces | 171 | 0 | 0 |

Classified chemical substances

| Ⅰ | Ⅱ | Ⅲ | |

|---|---|---|---|

| Number of workplaces | 70 | 0 | 0 |

Lead

| Ⅰ | Ⅱ | Ⅲ | |

|---|---|---|---|

| Number of workplaces | 1 | 0 | 0 |

Control class I: Work environment management is appropriate

Control class II: Work environment management has room for improvement

Control class III: Work environment management is inappropriate

Regarding control class II workplaces

Organic solvents

Causes: Decreased effectiveness of local exhaust ventilation systems

Temporary countermeasure: use of gas masks

Permanent countermeasure: Installation of push-pull ventilation system completed

Particulates

Causes: inadequate particulate filter management, reduced effectiveness of local exhaust ventilation

Temporary countermeasure: use of particulate respirators

Permanent countermeasure: review of daily inspection and cleaning regime, planned expansion of local exhaust ventilation capacity

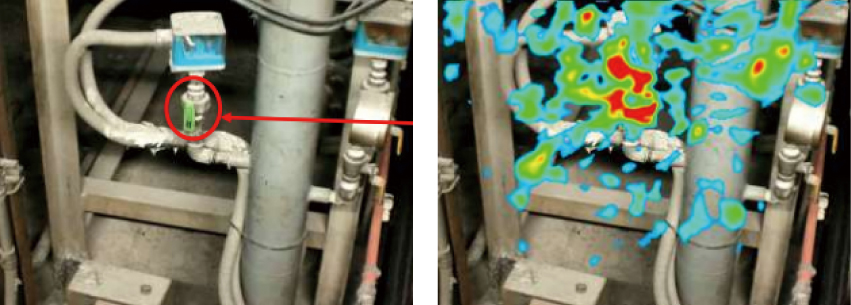

We promote the efficiency of work environment upgrades by visualizing workloads through ergonomic evaluations targeted at preventing illness. This is achieved using an AI camera–based automated analysis system developed in-house.

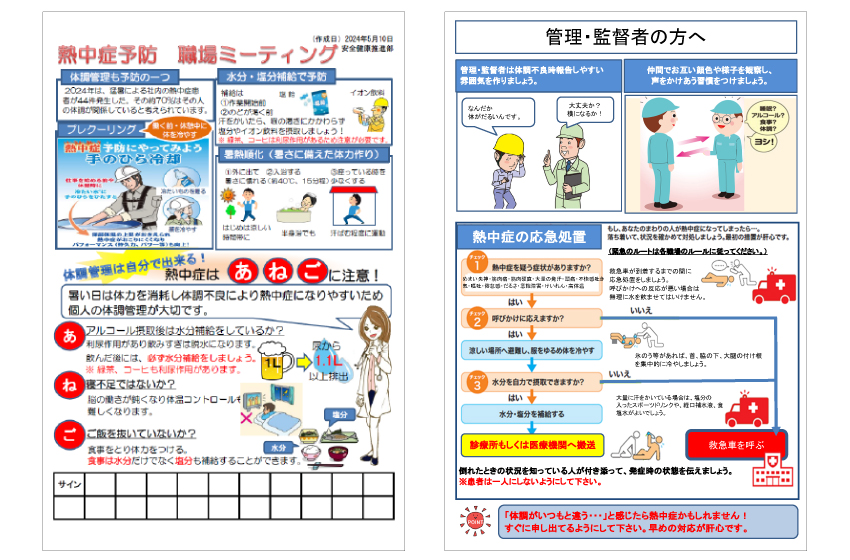

Heatstroke prevention measures

Based on the Cool Work campaign published by the Ministry of Health, Labour and Welfare, Aisin appoints one heatstroke prevention officer from each workplace to manage preventative activities.

Annual plan

May

Heatstroke prevention officer briefing and study session

June

Heatstroke prevention education for all employees (video, live meetings)

July–September

Supervisor outreach activities (reminders after rainy season and holidays)

November

Activity review meeting (report on current fiscal year, exchange requests and opinions for the upcoming year)

Number of heatstroke incidents by instigating factor

Record-breaking heat was reported nationwide in FY2025, leading to an increase in cases. While human factors (individuals' inadequate health precautions) were frequently cited as causes, our educational activities, early detection, and prompt response resulted in zero work-related absences.

Heatstroke Prevention Workplace Meeting Sheet

Fire Prevention

Efforts to Prevent Fire Recurrence and Minimize Damage

Twenty-eight years have passed since the February 1, 1997, Kariya Plant fire. Following subsequent hires and integrations, only about 20%–30% of employees have direct knowledge of that time. Members of upper management, including our executives, are concerned that awareness of the circumstances may fade with time.

To prevent a repeat of past failures, our leadership personally communicates lessons learned from past failures and hardships and conveys messages they want employees to understand and feel. Thus, continuing efforts are made that connect with each individual's awareness and actions.

Furthermore, as part of our efforts to preserve our institutional memory, we are taking initiatives to memorialize past fire incidents for future generations by producing videos featuring testimonials from those involved.

AISIN Group Unified Six-Point Fire-Prevention Program

Starting in FY2024, we reanalyzed past fires and systematically catalogued the primary causes and compiled preventative measures for each—management of ignition sources and combustible materials, electrical fire countermeasures, duct management, etc.—into six high-priority fire prevention elements. We then mapped the fire prevention management status.

Through this activity, we are visualizing the management status level across the entire AISIN Group and promoting improvement activities.

Six key elements of fire-prevention

- Management of ignition sources and combustible materials (risk assessment and clarification of management issues)

- Hazardous material management (maintenance and inspections in accordance with laws and regulations)

- Strict enforcement of on-site hot-work rules

- Electrical fire prevention

- Duct management (clarification of inspection and cleaning rules)

- Initial fire suppression to minimize damage (four basic fire responses)

Fires may occur in the presence of an ignition source, combustible materials, and oxygen.

Enhanced management of fire-critical equipment

Equipment that may provide an ignition source is registered as requiring priority fire management (F-compo facilities*) to strengthen prevention controls. Such equipment represents a high fire risk due to the presence of ignition sources and combustible or flammable materials or posing a significant risk of major damage in case of fire. By clarifying management responsibilities related to fire prevention and ensuring compliance and maintenance, we aim to prevent fires before they occur.

F-compo facility: a facility with fire-related components (ignition sources, combustible materials, and firefighting equipment) to be managed

Key management issues

| Title1 | Title2 |

|---|---|

| Ignition sources |

|

| Combustibles |

|

| Fire suppression |

|

F-compo facilities

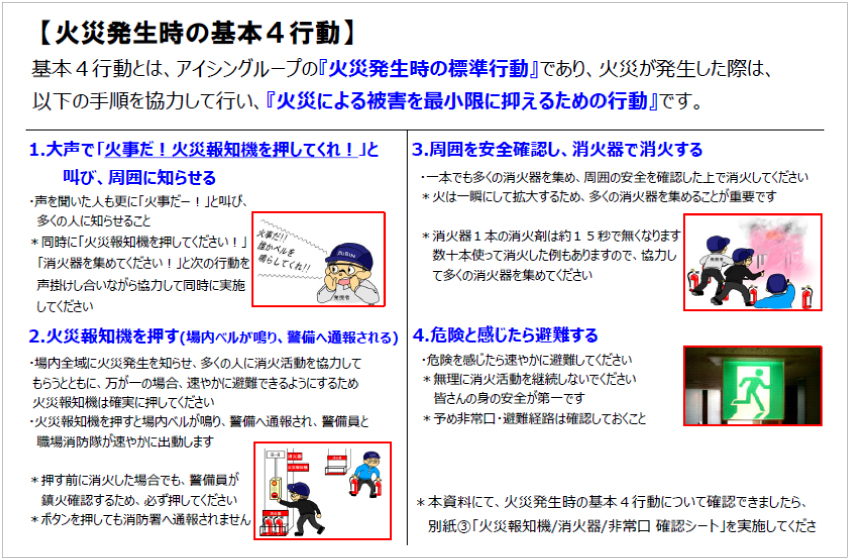

Four basic actions during a fire

To minimize damage through the prioritization of human life and the promotion of swift initial firefighting efforts if a fire manages to occur, the Group has standardized four basic fire responses.

To ensure understanding of the purpose of these responses, we regularly hold workplace meetings and execute training using fire alarm simulations and fire extinguishers. Furthermore, in recent years, we have begun introducing VR fire extinguishers at some facilities to further enhance the training environment.

Workplace meetings

Fire warden development

At Aisin, we appoint fire wardens at each facility. Through education and various collaborative activities, we deepen our shared knowledge and expertise in our quest to develop personnel capable of becoming fire wardens.

Fire prevention surveillance

To maintain and elevate our system of fire prevention management, Aisin implements a fire prevention surveillance program with the involvement of third-party inspections and evaluation.

As we make improvements based on the results, we purchased leading-edge measuring equipment used in the FY2025 surveillance exercise and have incorporated gas leak diagnostics and other functions into our own processes.

Implemented in FY2025:

Seven Group company sites