Society

Basic stance and policy

Aisin upholds its motto, “To our customers, inspiration and trust,” as a component of its value proposition and focuses on quality to create new value that exceeds customer expectations.

Furthermore, the Company places Quality Supremacy mentality at the core of its corporate guidelines, the Charter of Sustainability, and its guidelines for individual behavior, the Aisin Group Way. We are dedicated to enhancing not only our products and services but also the quality of our work. All employees cooperate with each other to promote TQM*1 as a fundamental force in improving our corporate structure based on the principle of putting the customer first.

Total Quality Management

Our policy on quality is defined as follows, and the framework for quality assurance activities is stipulated in our Quality Manual.

Policy

By pursuing— with due consideration for safety and the global environment—the quality our customers demand throughout the commercial lifecycle, we are able to offer products and services that inspire delight and happiness on a timely schedule as we help sustain a security and comfort society.

Promotion Structure

The AISIN Group Quality Division bears responsibility and holds authority for maintaining quality across the entire Group and plays a central role in guaranteeing our customers receive quality goods and services.

To provide satisfaction and peace of mind to our worldwide customer base, we implement our quality policy across our product and functional divisions, centered on Quality Function Deployment meetings. We monitor quality improvement initiatives in accordance with this policy, constantly gathering opinions from customers and providing companywide feedback. We also perform audits and provide quality training to drive product development advancement.

In response to recent certification irregularities within the Toyota Group and quality issues at our North American subsidiary, our senior management has become directly involved. In an effort to restore trust, we have established a new Group Regulatory Certification Committee and tasked cross-functional teams with initiatives aimed at raising product quality. Furthermore, we are driving a shift in mindset by thoroughly imbuing our workplace culture with Quality Supremacy ethos and actively listening to voices from the front lines.

Strategy

Ensuring customer peace of mind and safety by establishing a global system that delivers the highest quality

- Building, auditing, and improving our global quality assurance framework (Quality Management System) by addressing next-generation products and service quality, and strengthening governance

- In a digitally transforming (DX) society, cultivating talent capable of adding value amid progress with such growth domain as electrification and carbon neutrality

Key initiatives

Ensuring reliable quality assurance throughout development to production processes for medium-to-long-term growth.

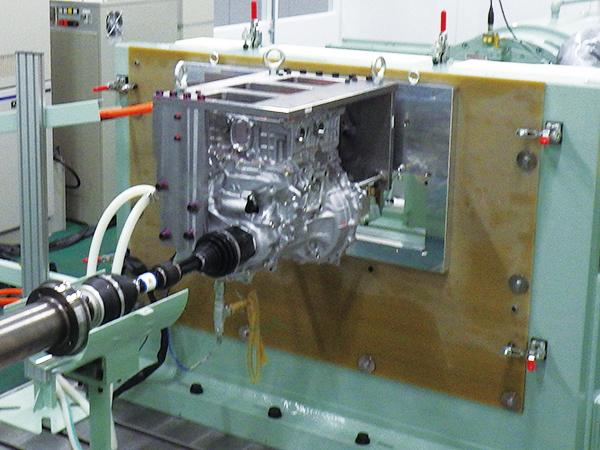

Specialized departments from product design, production engineering, and factories collaborate on electrification from the product design stage. We are shortening development cycles through digital innovation in the development process. For new product launches, detailed implementation guidelines are created within the quality assurance framework, and quality is rigorously assessed at key milestones throughout the process. During development, we reevaluate safety and regulatory compliance from the customer's perspective, consolidate technical expertise and insights across product lines, and work to improve design quality by incorporating lessons learned from past failures. For quality evaluation, we use proprietary test courses and facilities that replicate challenging environments found at sites around the world, including extreme temperatures, rough and icy roads, and electromagnetic interference, to comprehensively assess the functionality and performance customers demand of automobiles. Moreover, during preparation for production, we leverage cutting-edge digital technologies such as production line simulations to rapidly establish highly refined production systems. We then run multiple mass-production trials to ensure stable output and continuous quality advancement.

Reliability assessment at product development stage

Comprehensive assessment of required automotive functions and performance

Aisin, ahead of other automotive parts manufacturers, constructed a comprehensive test facility with a circuit as early as 1970. Using test courses replicating road conditions worldwide and state-of-the-art equipment, we continuously verify and pursue the performance and durability of our products.

Testing under replicated regional environmental conditions

To confidently deliver high-quality products to our customers, we run in-house testing that replicates distinct environmental conditions from various geographic locations.

Multifaceted testing from a user perspective and immediate feedback of results into product development allow us to reliably meet growing demand for enhanced reliability.

Comprehensive testing facility

Conducts comprehensive multipronged evaluations of vehicles and products at such facilities as low- and high-temperature chambers, anechoic chambers, and engine test benches

Conducts evaluations under simulated icy road conditions and a range of test tracks replicating road conditions from around the world

The first North American test facility established by a Japanese auto parts manufacturer

Commitment to resolving customer issues at the first complaint and using of big data to avert problems

For every initial report of a customer complaint, whether relating to newly launched or existing products, information is disseminated to relevant departments, including overseas locations. The entire group works together to minimize inconvenience for the customer. We thoroughly investigate root causes with an eye not only to product countermeasures but also work processes improvements to keep incidents from recurring. We apply the lessons learned through this process to improving product development.

Furthermore, to reduce and eliminate customer complaints, we are advancing activities that utilize big data obtained from vehicles and products to detect early signs of potential failures before they occur, enabling diagnostic and predictive measures.

Additionally, aiming for quality products that exceed customer expectations and delight users, we look at feedback (including social media content) and visualize indications of customer dissatisfaction. We incorporate our findings into our quality improvement process.

Building a workplace culture and people who thoroughly pursue “Quality Supremacy ”

To restore our fundamental Quality Supremacy ethos to its previous status, we engage employees from three vantages: knowledge, wisdom, and context. We focus on spreading knowledge through educational channels that explain the meaning of Quality Supremacy in a modern setting. We appeal to wisdom through our Densho-kan, which displays compelling cases of failure, and quality-focused exhibitions that emphasize actual product displays. We put all this into the context of our workplace culture, where everyone naturally prioritizes quality in all tasks. To this end, we hold quality-themed lectures, set up dialogues on quality among employees and top management, and stage workplace-level quality meetings.

Beyond QC circle activities, through daily operations we are strengthening the foundation from which we develop staff and guide workplace culture. This includes requiring all employees to submit annual Quality Action Declarations, which are subject to monthly review, and annual self-assessments of individual tasks based on the three elements of the Quality Supremacy mindset.

Three elements of the Quality Supremacy ethos

Quality Management System

Aisin has established a quality management system compliant with IATF 16949*3. All employees work together as one to execute quality assurance procedures, thereby ensuring that we deliver satisfaction and peace of mind for our customers. As of May 2025, 52 production sites had obtained IATF 16949 certification.

IATF16949: Quality Management System specifically for the automotive industry

Quality assurance training

We implement quality-focused activities for all employees across the 12 Group companies, with action guidelines uniformly based on the Quality Supremacy mindset. For new hires, we convey our Quality Supremacy values and the importance of quality through visits to the quality training zone at the Densho-kan.

Additionally, we provide training in quality assurance for all levels: QC and quality management training for skilled workers, problem-solving training for administrative and technical staff, and management training for supervisors.

Through companywide lectures on quality, quality-focused dialogue sessions with executives, and quality-themed exhibitions held at all factories, we instill the idea that every employee must focus on quality in all operations as viewed from the customer's perspective and pass down individual expertise related to quality. Foty quality training courses covering QC, reliability, data analysis, etc., have been converted to an e-learning format to enable access anytime, anywhere, and by anyone. After completion, themed consultation sessions and networking events are held to hone practical skills. We develop our staff across the entire Group based on this training.