News

AISIN Group products contribute to improved fuel efficiency and driving performance of Toyota Corolla Hatchback (North American model)

Jul. 3, 2018

News Release

Various AISIN Group products are included in the Toyota Motor Corporation's new Corolla Hatchback (North American model), contributing to improvements in both fuel efficiency and driving performance. The latest model of the Corolla Hatchback features further improvements in environmental performance and basic driving performance, with a platform developed through the Toyota New Global Architecture, Toyota's structural reforms for vehicle development aimed at optimizing driving performance.

Aisin AW Co., Ltd. developed the Direct Shift-CVT (Continuously Variable Transmission) jointly with Toyota, a new type CVT that combines outstanding fuel efficiency, 6% better than the current product, with direct and powerful driving performance. The world's first starting gear enables direct and powerful starting and acceleration and top-class gear ratio range. High-speed shift control technology, cultivated through the company's expertise with automatic transmissions, is utilized for the switch from gear to belt. Also, the CVT belt is narrowed and the diameter of the pulley reduced, increasing the shift speed by 20% for a smooth shift and powerful, rhythmic driving performance. (This product is produced by Toyota Motor Corporation.)

Middle Torque Capacity FWD 6-Speed Manual Transmission of Aisin AI Co., Ltd. has a weight reduced by 7 kg and overall length reduced by 24 mm, making it one of the world's most compact products of its type and contributing to improvement of vehicle fuel efficiency. Also, its miniaturized design enables greater freedom of vehicle layout, making positive contributions to design, safety, and driving performance. Synchromesh for reverse gear is added to prevent gear noise when reverse shifting. In addition, it is compatible with iMT control, which supports drivers' smooth shift operation.

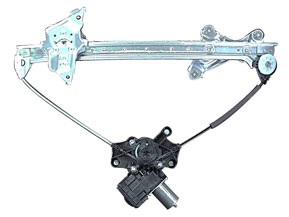

The new Corolla Hatchback model is also equipped with Piston for Gasoline Engines of Art Metal Mfg., Ltd., Exhaust Manifold of Aisin Takaoka Co., Ltd., and Window Regulator of Shiroki Corporation, products newly developed to contribute to improved fuel efficiency.

The Piston for Gasoline Engines achieves low-friction performance by applying laser processing technology instead of the conventional particle collision method for surface processing of the piston skirt. Low friction and low seize resistance are achieved by creating crosshatched narrow grooves with a laser on the smoothed surface.

The Exhaust Manifold features a shape newly developed for this vehicle's engine, with the exhaust collector part given a V shape that leads exhaust gas smoothly to catalyzation. In addition, by reducing the bending radius of the pipe and making it compact, with thin sheet material, a mass reduction of 20% is achieved.

The Window Regulator improves lift quality and reduces weight by 0.6kg, by switching from the arm-type regulator of a conventional pressed product to wire-driven ascent and descent. This structural change enables effective utilization of space inside the door for pockets etc.

Product photos

■Direct Shift-CVT

■6-Speed FWD Manual Transmission for Middle Torque Capacity Applications

■Piston for Gasoline Engines

■Exhaust Manifold

■Window Regulator