Test ride event for Aisin's new electrification technologies demonstrates how ultra-compact eAxle revolutionizes vehicles

Nov.29, 2022

The automotive industry is at a major turning point in the quest to attain global Sustainable Development Goals (SDGs). There is growing momentum toward powertrain electrification due to the shift from internal combustion engines (ICEs) to electric motors.

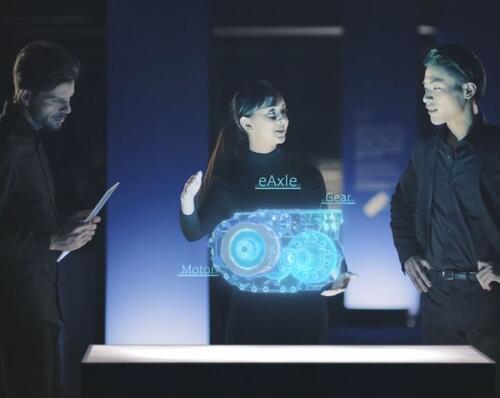

Aisin has been working to achieve carbon neutrality in terms of both production and products. We offer a full lineup of electric units including eAxle, which is installed in hybrid vehicles, battery electric vehicles (BEVs) and 1-motor hybrid transmissions. Notably, eAxle is regarded as the most important strategic product to drive BEVs, and the demand is expected to increase in the future. Aisin has been accelerating its development jointly with BluE Nexus Corporation* and DENSO Corporation.

* BluE Nexus is a joint venture established with DENSO in 2019. It specializes in the development, adaptation, and sales of electrification systems and electric drive modules. (At present, Aisin and DENSO have a stake of 45% each, and Toyota Motor Corporation has a stake of 10%.)

In September 2022, we held a test ride event for new electrification technologies at the Aisin Fujioka Proving Ground in Toyota City, Aichi Prefecture, inviting the press to see some of what is under development at Aisin. This article focuses on Aisin’s electrification efforts, including information released at the event.

Aisin’s continued commitment to higher efficiency and downsizing

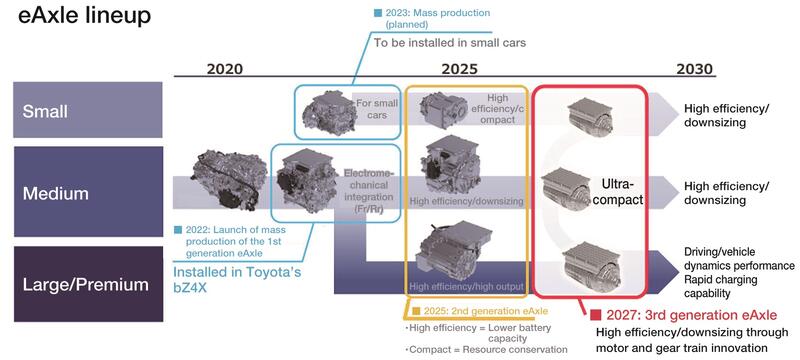

As the energy situation varies in each country and region, so do the lifestyles of people who use vehicles. To quickly meet the electrification needs of global customers, Aisin has been accelerating the development of technology to achieve the roadmap below, originally announced in November 2021.

Aisin’s strength lies in the combination of its technologies and products, including the gears, shafts, and casings that have been refined in the development of automatic transmissions (ATs) over the past 50 years. Another strength lies in our ability to apply and adapt the production equipment for electric units to achieve further development. We can also harness our high-efficiency and downsizing technologies, which have been refined in the development of ATs and eAxle.

In 2020, we started mass production of eAxle by taking advantage of these strengths. In 2022, eAxle evolved into the 1st generation eAxle,* which integrated the gear, motor, and inverter for controlling the motor. The 1st generation eAxle is manufactured for front wheel drive (FWD) and rear wheel drive (RWD) vehicles. It is also installed in Toyota’s bZ4X and the new Crown.

* Jointly developed by BluE Nexus, Aisin, and DENSO

In 2025, three types (Small, Medium, and Large/Premium) of the 2nd generation eAxle will be launched for a variety of cars depending on the size and application.

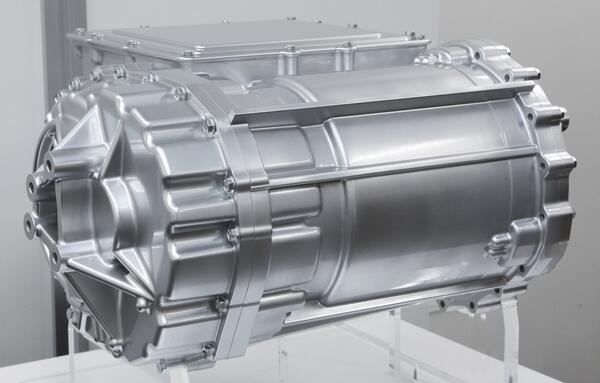

2nd generation eAxle for Large/Premium (large capacity) unveiled at the test ride event

To further increase efficiency and improve the overall electric mileage of a vehicle by more than 10%, we have been working to minimize the resistance generated during rotation of the motors and gear.

If electric mileage can be improved by 10%, a smaller battery can be installed in a vehicle. This will significantly contribute to reducing the weight and cost of vehicles.

Goal: Reducing the size by half

In July 2021, Aisin established the Advanced Powertrain Development Department to accelerate the planning and development of powertrains following the 2nd generation eAxle. Drastic evolution and advanced development of the 3rd generation eAxle became the next priority and in less than a year, a prototype was completed in the spring of 2022.

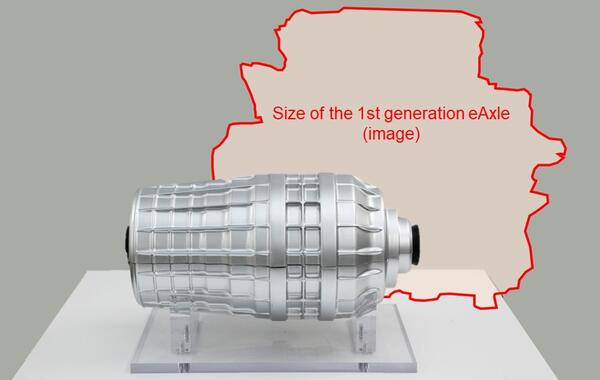

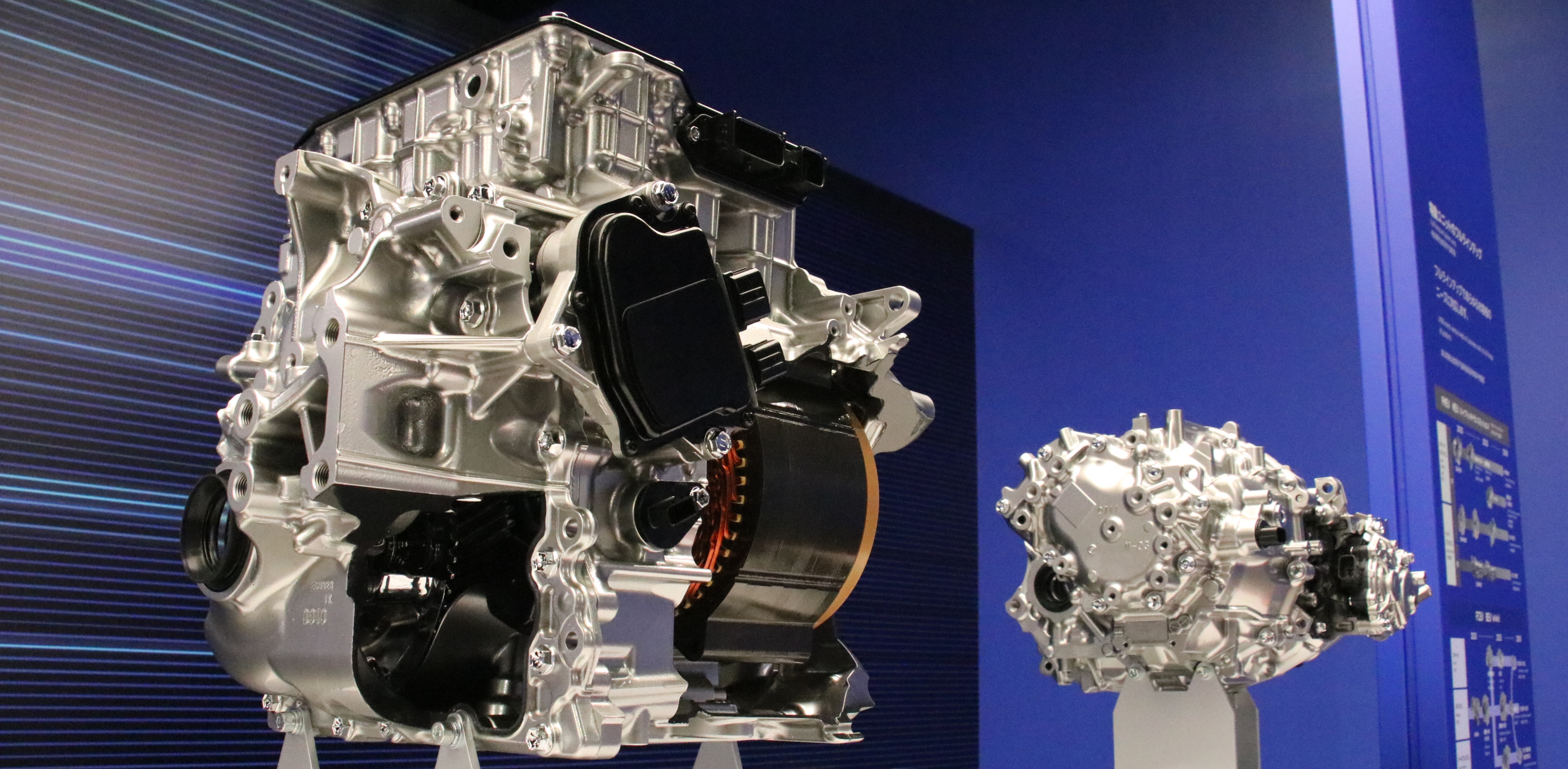

The product is expected to be released in 2027 and is characterized by an amazingly compact design as seen in the photo below. The development goal of the 3rd generation eAxle is to reduce the size (volume) by half compared to the 1st generation eAxle. Exhaustive efforts have been made to achieve downsizing.

Comparison of the size of the 3rd generation eAxle and the 1st generation eAxle

Higher efficiency and downsizing are ensured through motor and gear train innovation. The 3rd generation eAxle is compact and looks like like a cocoon with previously protruding parts shaved off and a weight reduction of about 30%. The 3rd generation eAxle is small but achieves smooth driving from initial take-off through powerful acceleration at high-speed range.

Powerful driving of test vehicle equipped with ultra-compact 3rd generation eAxle

eAxle can be installed in both FWD and RWD vehicles and can meet various electrification needs. Aisin believes that the spread of eAxle and its contribution to downsizing will reduce consumption of materials and achieve resource conservation for the product itself in addition to reducing waste and realizing carbon neutrality.

Immeasurable advantages of downsizing

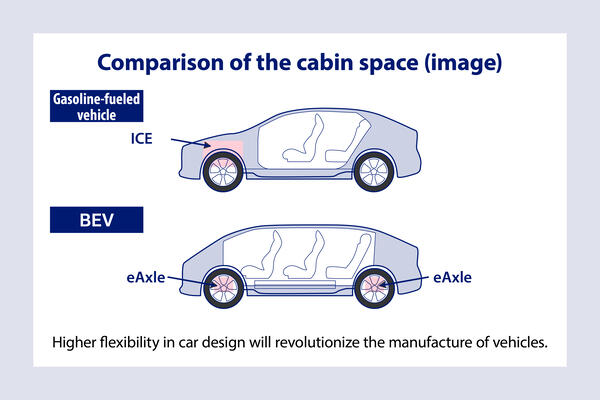

Replacement of vehicle powertrains with small electric units will increase flexibility in designing car bodies and interiors.

For example, it will become possible to design an almost flat floor from the front to the rear of a vehicle. Heavy batteries will be stored under the floor, and eAxle is placed in a low position. A lower center of gravity will further stabilize the vehicle, enabling better driving accuracy.

In terms of crash safety, there was a risk of the rugged engine block being thrust into the cabin in the event of an accident, resulting in injury to the occupants. An ultra-compact eAxle will help avoid such risk. It may become possible to change the design for body rigidity and impact absorption.

Aisin believes that it can significantly contribute to revolutionizing the design and marketability of vehicles by downsizing eAxle. We will meet the expectations of an electrified society by making all-out efforts to constantly develop advanced products and by harnessing technologies that have been refined through our operations.

The Aisin Group philosophy is “Inspiring ‘movement,’ creating tomorrow.”

We will continue to “inspire” global customers through efforts to electrify vehicles. The next issue will focus on Aisin Group’s electrification efforts in various fields other than eAxle and electric units.