How DX Expands Aisin's Operations: Executing a full lineup of electric drive units while reducing development time

Feb.28, 2022

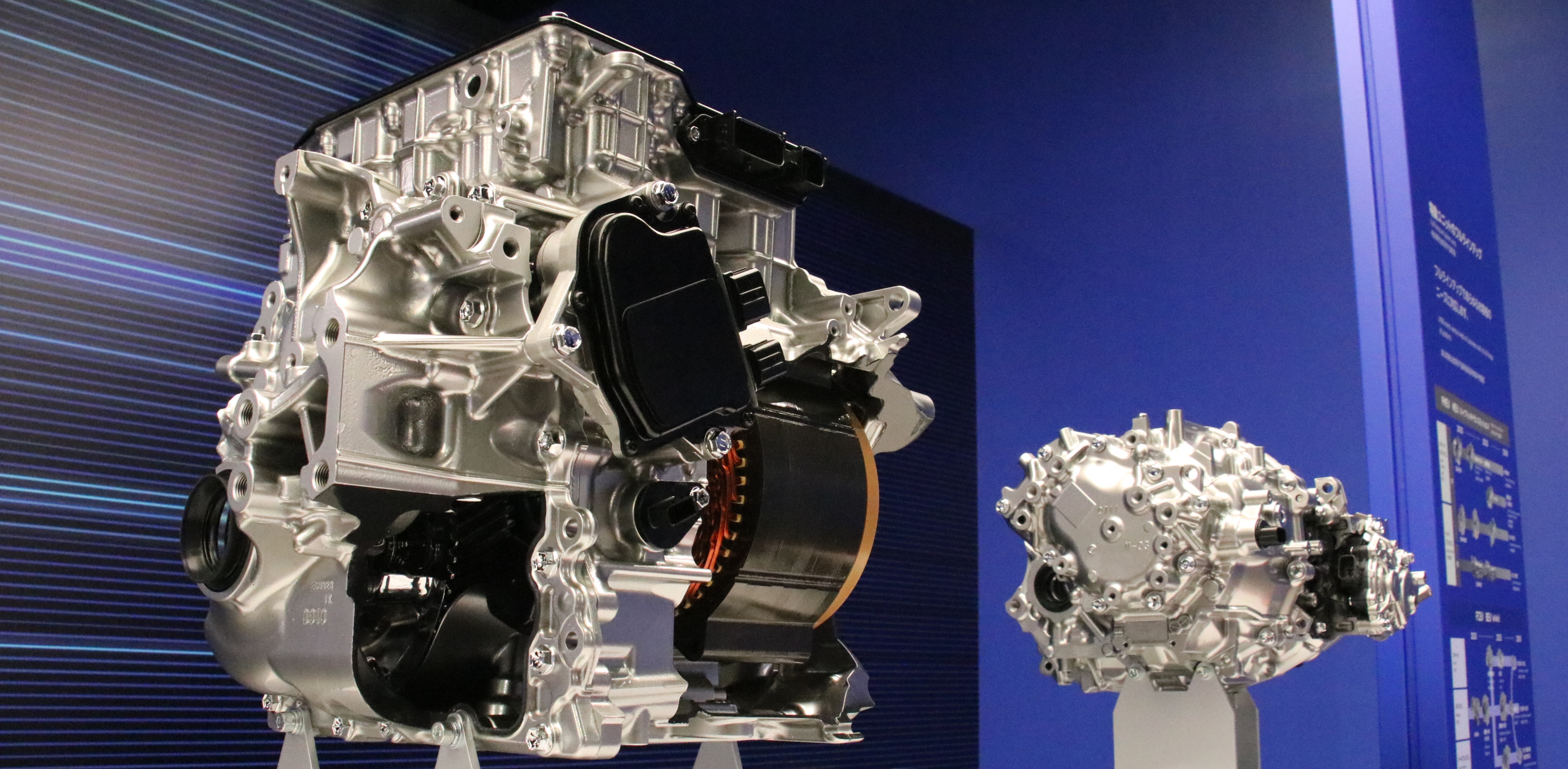

Aisin offers a full lineup of drive units for various types of electric vehicles, including HEVs, PHEVs, BEVs and FCEVs.*1 We believe that we can make a significant contribution toward carbon neutrality by staying close to the energy and infrastructure conditions across the world to provide units that are suitable for our customers' needs. However, it is not easy to accelerate the development of products to meet the increasing demand for BEVs while at the same time enhancing the lineup of conventional products, such as those for HEVs.

*1 HEV: Hybrid electric vehicle

PHE: Plug-in hybrid vehicle

BEV: Battery electric vehicle

FCEV: Fuel cell electric vehicle

Transforming the development process through digital technology.

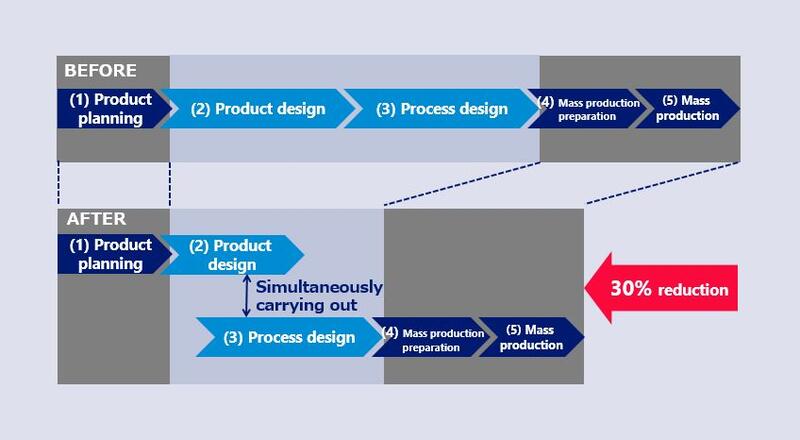

To provide a wide range of products for electric vehicles in a timely manner, we need to dramatically accelerate our development speed. Aisin set a goal of a 30% development time reduction by 2025, and achieving this goal will require incorporating digital transformation (DX) into the development process.

Designing with 3D models and verifying them virtually

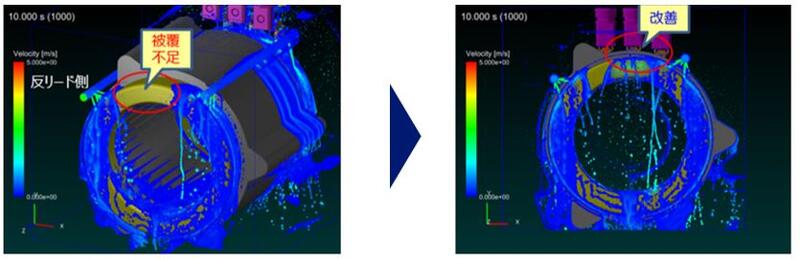

Aisin has introduced model-based development (MBD) into its product development process. MBD is a development methodology based on a 3D model reproduced on a computer and verified through simulation. In the past, design work was performed by physically creating prototypes and repeatedly evaluating them to improve quality. However, this method requires repeated re-creation of prototypes with each trial and error step - at an enormous expense of time and cost.

In contrast, MBD uses 3D models and supercomputer simulations to allow design work and verification in a short cycle without making prototypes, thus enabling highly accurate design at a much earlier stage.

Simultaneously carrying out downstream step using 3D model

The introduction of MBD has a positive impact not only on product design, but also on the overall development process.

The conventional development process consisted of 1) product planning, 2) product design, 3) process design, 4) mass production preparation and 5) mass production. Due to the introduction of MBD, a design close to perfection can be created at the early stage of (2) product design and the following step, (3) process design, can be carried out using the created 3D model simultaneously. By proceeding with two steps at the same time, the development period can be shortened significantly.

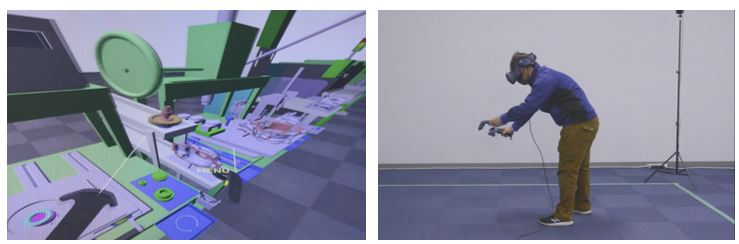

Simulating process design by VR technology

Furthermore, we have started to use virtual reality (VR) to verify the workability in (3) process design. The verification of workability is to check the movements of workers, the ease of equipment maintenance, etc. Traditionally, we set up a “mock” production line at the actual site and verified the validity of operations. Inevitably, much rework occurred which extended the preparation period.

Using VR, a virtual production line is reproduced in the VR space and a person enters to verify the workability. By simulating actual operations and identifying issues at an early stage, we are able to prevent the time and expense of rework and carry out the production preparation more quickly.

Supporting process transformation with unique platform

Development using 3D models and VR requires us to totally reform the existing rules and business processes.

To address this issue, Aisin has developed the v.Platform, which manages the entire process, from design to production. The v.Platform is a tool that can record all information related to development, including 3D models and other deliverables, as well as the development background, issues and evaluation data. By visualizing data transfer and other communication between operations as well as in the entire process, it makes it easy to review the rules and restructure the processes.

Aisin has dared to develop this platform on its own. As the product development process changes and becomes faster, the tools that support it must also change quickly. For now, v.Platform will mainly be used for the development of new products for electric vehicles, and we will expand the scope of its use to other products in the future.

Aisin is consistently reviewing existing systems and rules, such as the new development process described here, and implementing various reforms. We will continue to actively incorporate digital technology and promote the electrification of mobility in order to reach our goal of a carbon neutral society.