Eco-Friendly Rust Remover Wins Environment Minister's Award for Cutting CO₂

Oct.20, 2025

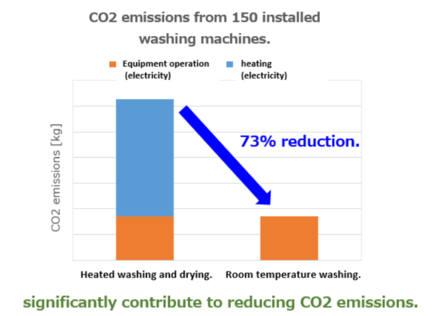

Innovative Rust-Preventive Cleaning Agent Cuts CO₂ Emissions by 73%

Rust prevention is a critical challenge in maintaining the reliability of metal parts, especially in vehicle manufacturing. To address this, AISIN and Kao Corporation have jointly developed an innovative, room-temperature rust-preventive cleaning agent. This breakthrough not only offers excellent rust protection but also significantly reduces environmental impact—cutting CO₂ emissions by up to 24 tons annually per cleaning machine.

We spoke with three key members of the development team to learn more about the journey behind this award-winning solution. Their collaboration recently earned the Minister of the Environment Award at the 52nd Environmental Awards, recognizing the project’s major contribution to sustainability in industrial processes.

A Cleaner Process with Major Environmental Gains

What sets this cleaning agent apart is its ability to perform effectively at room temperature. Traditionally, cleaning processes required heating solutions to around 60°C and drying with hot air—both energy-intensive steps that contributed heavily to CO₂ emissions. The new agent eliminates the need for heating and drying entirely, leading to an impressive 73% reduction in CO₂ emissions compared to conventional methods.

Less Waste, Lower Costs: A Smarter Way to Clean Metal Parts

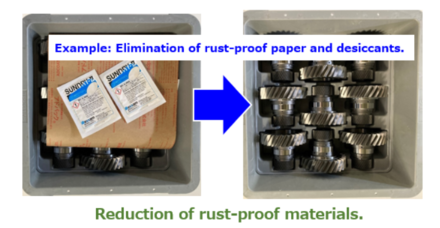

The new cleaning agent doesn’t just reduce CO₂ emissions—it also delivers major savings in materials and resources. Thanks to its rust-preventive performance, the need for additional materials such as rust inhibitors, desiccants, and bulky packaging for storage and transport has been significantly reduced. Water usage is now less than one-third of what was previously required, leading to much lower wastewater treatment costs. Additionally, because the agent works effectively at room temperature, it degrades far more slowly, tripling its shelf life compared to conventional solutions.

Rethinking the Cleaning Process: A Project Sparked by a Challenge

The drive to innovate began in 2017, when Takayuki Hisano received a pointed observation from his supervisor: “There are too many cleaning steps in our metal parts production. If we don’t change, we’ll fall behind our competitors.”

While production staff worked diligently to protect parts from rust, the process itself had become inefficient. Multiple cleaning steps were used just to remove rust-inhibiting oils, many of which added little actual value. Worse still, aluminum parts shipped overseas were sometimes returned due to rust.

“We knew something had to change,” said Hisano. “So we started by focusing on the cleaning solution itself—rethinking how we could simplify the process and reduce the environmental impact.”

From a Cold Call to a Collaborative Breakthrough

Hisano and his team quickly reached out to existing suppliers, requesting proposals for a better cleaning solution. At the same time,Hisano had a bold idea: to explore joint development with a leading detergent manufacturer. Without high expectations, he called Kao Corporation’s customer service line. To his surprise, he was transferred directly to the engineering division.

Just one week later, a Kao sales representative and a researcher traveled from Tokyo to visit AISIN. As an engineer, Hisano immediately felt a sense of connection. He was impressed by Kao’s collaborative spirit, wealth of ideas, and fresh perspectives. Confident in their shared vision, he decided to move forward with them. At this early stage, however, reducing environmental impact was not yet the primary goal—it was all about improving the cleaning process.

Cross-Industry Collaboration Fuels Innovation

Once joint development began, aligning expectations between the two companies became essential. As a result, monthly meetings were established to maintain close communication and collaboration.

“For Kao, the standard cleaning process includes cleaning, rinsing, and drying,” Hisano explained. “But in automotive manufacturing, it’s typically just cleaning followed by drying. This difference in process was a bit of a cultural shock for them.”

Bridging these differences through open dialogue helped both sides better understand each other’s industries—laying the groundwork for innovation that exceeded initial expectations.

Overcoming Challenges Through Collaboration

While the joint development project between AISIN and Kao saw major successes, it wasn’t without its challenges. Differences in perspectives were evident, but more importantly, they became opportunities for learning and growth. Over the course of the project, the two companies held about 80 face-to-face meetings to ensure close, consistent communication. When AISIN requested changes, Kao often responded with detailed proposals by the next meeting.

“We were amazed by their speed and technical depth—it pushed us to aim even higher,” said Hisano.

The collaboration truly leveraged the strengths of both companies. For instance, an automatic acid-based titrator was introduced to improve the precision of concentration control for the cleaning agent. AISIN’s expertise in mass production and quality control was then applied to ensure consistent quality of the agent’s key components.

On-Site Adoption Driven by a Shared Commitment to Quality

A critical step in the project was implementing the new cleaning agent on the production floor. Although the solution promised major benefits, its introduction also brought new management challenges, requiring the understanding and support of on-site staff.

To begin, the project team partnered with the Quality Assurance Department to propose a pilot implementation on aluminum parts at AISIN’s Okazaki East Plant. Once the team clearly communicated how the agent would enhance product quality, plant staff quickly got on board. This understanding led to successful implementation in cleaning machines used in assembly.

The project team’s strong commitment to quality and their proactive engagement with plant staff earned trust quickly. When the new agent delivered clear, positive results, other production lines began requesting it, resulting in its rapid expansion throughout the plant.

From Quality to Sustainability: Evolving the Mission

By 2021, environmental awareness was growing within AISIN. The team proposed expanding the use of the cleaning agent—not just for quality improvement, but also for CO₂ emissions reduction. This shift led to the development of a next-generation cleaning solution with three major strengths: excellent cleaning performance at room temperature, the ability to dry without hot air, and strong rust prevention without additional treatment.

Ken Ishikawa, above, who led the production engineering side of the project, oversaw the plant-level implementation of the completed room-temperature, rust-preventive cleaning agent—bringing the innovation full circle from concept to practical, sustainable use.

From Challenges to Commitment: On-Site Implementation Led by Teamwork and Trust

“When implementing the cleaning agent at the plant, I didn’t just focus on replacing the solution—I tackled each issue one by one, starting with ensuring quality,” said Ken Ishikawa, who oversaw the rollout on the production floor.

One of the biggest challenges was the increased workload for on-site staff, who now needed to carefully manage the cleaning agent’s concentration and composition. Open and honest communication was key to gaining their understanding and cooperation. Ishikawa also highlighted the broader business impact of the switch. “Cleaning at room temperature reduces energy costs, which in turn lowers the cost of our automotive parts and improves profitability,” he noted.

Thanks to strong interdepartmental cooperation and patient dialogue, the team was able to bring everyone on board.

A Culture That Supports Innovation

The successful implementation was also made possible by AISIN’s corporate culture—one that values logical reasoning and supports energy-saving initiatives. Yuta Takeuchi, who led carbon neutrality efforts at the plant, was a strong advocate for adopting the room-temperature, rust-preventive cleaning agent. “It was clear that this solution could significantly cut CO₂ emissions,” he said. “But I couldn’t make the decision alone.” Takeuchi worked hard to secure buy-in across multiple departments—manufacturing, cost planning, quality, and inspection.

“It was challenging to help every stakeholder fully understand the benefits,” he recalled. Fortunately, plant leadership, including the general manager and supervisors, took the time to listen. Their willingness to support a forward-looking solution played a major role in moving the project forward.

The results were immediately visible. “We saw a noticeable reduction in steam and electricity use,” said Takeuchi. As awareness grew, on-site staff began taking initiative themselves—experimenting with things like more efficient air-blow techniques to maximize performance. “Their proactive involvement was both impressive and encouraging. The entire plant truly came together as one team,” he added with a smile.

Looking Ahead: Expanding Adoption and Driving Environmental Impact

The innovative cleaning agent developed through AISIN’s collaboration with Kao has already been adopted at approximately 21 plants in Japan and overseas, with about 700 cleaning machines in use—400 of which utilize the room-temperature rust-preventive version (as of June 2025).

Thanks to its smooth implementation and strong environmental performance, the room-temperature cleaning agent earned the prestigious Minister of the Environment Award at the 52nd Environmental Awards, hosted by the National Institute for Environmental Studies and Nikkan Kogyo Shimbun, with support from the Ministry of the Environment.

Looking forward, expectations continue to grow for this solution’s potential to further reduce environmental impact and operational costs. AISIN plans to actively promote its deployment across more group companies and suppliers, while also exploring opportunities for external sales and wider market adoption.

Paving the Way for a Future Without Cleaning Machines

Winning the Minister of the Environment Award was just the beginning. Now, Hisano has set his sights on an even more ambitious goal: creating production lines that no longer require cleaning machines at all.

“If our suppliers adopt this cleaning agent, they can significantly reduce CO₂ emissions from their own cleaning processes,” Hisano explained. “They won’t need to apply rust-inhibiting oil, which means we won’t need to remove it—eliminating cleaning steps at our plants before assembly. That’s a major cost saving and a big reduction in workload for everyone on the shop floor.”

With this bold vision, the team has already begun tackling their next challenge—driving innovation toward simpler, cleaner, and more efficient manufacturing for the entire supply chain.