A Circular Economy and CO₂ Reduction Activities Underway in the Production Field

-Results Show Progress Toward Carbon Neutrality-

Sep.11, 2025

AISIN aims to achieve carbon neutrality by 2050 by striving for harmony with nature and providing contributions toward a sustainable future. To achieve the goal, we have been working on initiatives in terms of both products and production. In the field of production, we foster a circular economy and promote CO2 emissions reduction activities.

Plant operations reform to reduce resin waste by 75% and turn waste into resources

By 2030, AISIN’s Production Engineering Division set its target to reduce unnecessary material output (valuable materials and industrial waste) by 50% from the FY2023 level. Each plant addresses their own unique challenges and deploys their own strategic technologies. With plants steadily yielding results toward their targets, we were curious about initiatives that have generated measurable outcomes. We interviewed production engineersat the Shinkawa Kinuura Plant.

At the Shinkawa Kinuura Plant, resin is used to manufacture door locks and other body products. It was a major challenge to reduce the resin waste generated during processing. In addition to using mold structures that minimize the amount of scrap materials, an initiative is underway to recycle purge lumps and scrap shots, which were previously discarded.

Nobuhiro Takasu, who works on reducing resin waste at the Shinkawa Kinuura Plant, said:

“The molding temperature is critical for resin materials. To minimize waste from scrap shots - parts produced before molds reach the proper temperature - we assigned additional personnel and introduced a plant-wide recycling system that utilizes our existing crushers while heating molds to the target temperature.”

In the resin molding process, the resin which remains inside injection molding machines must be discharged when production is suspended due to a changeover. The discharged materials are called purge lumps. They were previously discarded because they could not be crushed due to the thickness and potential contamination with foreign matter.

“Previously, it was considered difficult to recycle purge lumps due to thermal degradation of physical properties. To challenge conventional wisdom to further promote a circular economy, we reexamined the properties of resin materials and found that some resins are prone to thermal degradation and that others may be recycled. During the study of new approaches using existing equipment, we came up with a technique to reduce thickness by feeding resin retained in injection molding machines into molds and molding the resin in the same process as that for our products. We thereby reduced formation of purge lumps. We repeatedly verified the quality and production requirements for practical application and succeeded in recycling purge lumps,” said Takasu.

These initiatives led to resin waste reduction by about 75%* compared to the FY2021 level.(*Reduction measured using resin waste levels in FY2024.) Both the amount of waste and the number of new materials purchased have been reduced, leading to a major accomplishment in reducing costs.

As environmental regulations become more stringent, requirements have been increasingly established regarding the recycled content percentage of resin materials. To properly meet social needs and attain company-wide carbon neutrality, Takasu recognizes the importance of breaking free from conventional approaches.

“We were able to deliver results thanks to close collaboration with manufacturing and quality control members beyond our department. Material recycling poses many challenges in terms of cost and quality, but it is essential to think creatively and take swift and agile actions.”

Reducing CO₂ emissions by 62% - Optimizing existing equipment to achieve carbon neutrality

CO2 reduction activities are also on track through optimization of energy consumption.

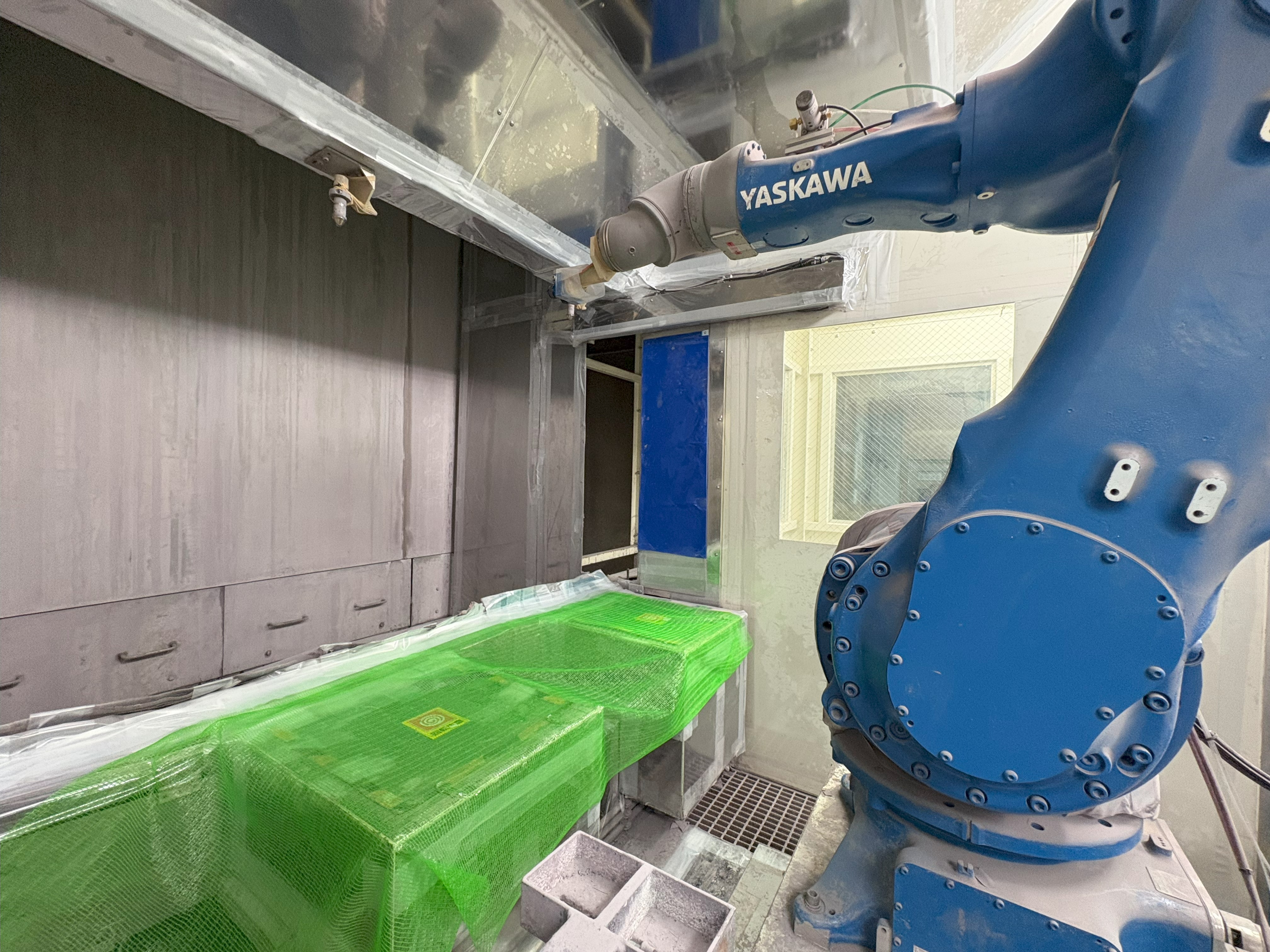

High levels of CO2 emissions posed a challenge in the spray coating process for exterior door handles,. To prevent defects in appearance in the coating process, the conditions during the paint spraying process like temperature and humiditymust be kept constant andair conditioning requires a lot of energy. Previously, efforts were made to enhance productivity to reduce CO2 emissions. To achieve further reduction, process improvements were made.

Daiki Kondo, a production engineer in the coating process for exterior door handles, stated how the initiative was launched:

“With technological advancement and changes in product specifications, I wondered whether the equipment layout and specifications, which were once considered optimal, are still optimal today. An investigation found that the volume and flows of paint mist generated in the coating process have changed significantly. The areas which were once exposed to mist are almost clear of mist. Based on this finding, I considered the possibility of reducing the air conditioning energy consumption by reviewing the unnecessary space. However, mere space reduction was likely to increase the defect rate due to mist buildup.”

In the coating process, paints are atomized and sprayed onto products. Inappropriate coating booth designs are likely to cause defects, such as coating irregularities on products due to paint mist buildup.

Kondo said that computational fluid dynamics (CFD) simulations were available thanks to the analytical personnel in the Production Engineering Division:

“We had to modify the existing equipment to reduce CO₂ emissions, but any defects would inconvenience customers. So, we thoroughly assessed the mist flow based on simulations. We increased the accuracy by correcting deviations relative to actual equipment. Eventually, we came up with a design capable of reducing the booth volume by 40% while maintaining the same processing conditions as before. Defects did not increase after the modification. We resumed production on the same day and attained the CO₂ emissions reduction target as planned.”

These initiatives led to successful reduction of CO₂ emissions by about 62% in the coating process for exterior door handles in FY2024 compared to the FY2013 level.

Successfully modified coating booth

“The key point of this initiative is that using existing equipment yielded the same CO₂ reduction effect to that of installing new equipment . This was made possible by understanding and cooperation amongthe plant members. Achievement of carbon neutrality requires company-wide commitment across all departments. This approach is also applicable to other products and processes beyond the coating process. I expect it to serve as a model example for maximizing the effects across the entire group,” said Kondo.

Rollout in the AISIN Group and a challenge to realize a circular economy with suppliers

In resin material recycling, an initiative is in progress to collect scrap materials from suppliers for crushing and recycling at AISIN.

“Many suppliers faced the same issues with disposal of resin materials. I learned that they gave up recycling because it was difficult to introduce crushers and secure personnel. So, I visited suppliers frequently to hold discussions and launched an initiative to build a recycling system together, with AISIN tasked with crushing and securing personnel,” said Takasu.

This was an unprecedented initiative, and there were no internal regulations or operational rules at AISIN. To enable the initiative, we promoted the activities in collaboration with plant members and many other departments in charge of material engineering, quality assurance, and design. We continually promote waste reduction throughout the supply chain while easing the burden on our suppliers.

Meanwhile, activities are also underway to share the knowledge of improving the air-conditioning efficiency in coating booths across the AISIN Group to companies like AISIN SIN’EI Co., Ltd., which has the same coating process for exterior door handles as that of the Shinkawa Kinuura Plant. At AISIN SIN’EI,CO₂ emissions have also been reduced.

Knowledge transfer outside of Japan to production bases in Turkey and Mexico has also begun . The knowledge will be shared across the AISIN Group, including other overseas bases.

Achieving carbon neutrality throughout the supply chain

Carbon neutrality cannot be reached by a single company. Ideas and knowledge developed by AISIN are disseminated to group companies and suppliers in and outside Japan to generate more measurable outcomes and reduce CO2 emissions throughout the supply chain.

“In addition to the initiative for coating of exterior door handles, we share ideas in various processes and yield results. Some products readily yield CO₂ emission reduction effects, while others do not. However, it is effective to challenge the conventional, taken-for-granted approaches from the viewpoint of ‘termination, abolition, and change’ for any manufacturing methods. I will share this concept to help generate more ideas into the future,” said Kondo.

AISIN will continue to take on challenges to realize a sustainable society by creating innovative solutions and yielding results in both products and production.