Report on Technology and Test Drive Experience Event: Electrification and Intelligence [Part 2]

‐ Improved safety and electricity efficiency with advanced intelligent technology -

Feb.10, 2025

![Report on Technology and Test Drive Experience Event: Electrification and Intelligence [Part 2]](/en/aithink/assets_c/2025/02/2024testdrive2-TOP-thumb-4032x2015-9814.jpg)

In August 2024, the Technology and Test Drive Experience Event: Electrification and Intelligence was held at the AISIN Toyokoro Proving Ground (Toyokoro-cho, Hokkaido). As the structure of the entire automotive industry undergoes rapid and extreme change, AISIN is also undergoing major transformations in its business structure.

In addition to the company’s existing areas like transmissions, where it has maintained a market advantage to date, AISIN is actively working on development in electrification and intelligence in the mobility industry. In the area of electrification, AISIN, as “the automotive parts manufacturer closest to automobile companies,” engages in comprehensive parts development, such as improving vehicle electricity efficiency by looking at the entire vehicle as an integral whole.

In Part 2, automotive writer Motoki Watase continues the journey after experiencing the drive unit described in Part 1. Next, Watase will introduce us to the new electrification and intelligence technologies unveiled at the technology and test drive event.

Electric disc brakes for improved braking feel

In recent years, methods for communicating the driver’s intent more quickly and accurately have evolved dramatically. In the early days of automobiles, when the driver operated the accelerator, brake, or clutch commands were transmitted via rods and cables, like those on a bicycle, via a mechanical link.

As technology advanced, hydraulic drive mechanisms were adopted to reduce the burden of operating effort (e.g. conversion from heavy steering to power steering) and to improve reliability. Even today, most vehicles use hydraulic braking systems.

However, mechanical links, which are a physical method of transmission, result in a slight time lag. To solve this issue, by-wire technology is a method of transmitting commands via electronic signals. In automobiles, turn signals have long been using by-wire technology, but in recent years, by-wire technology has also been adopted for the throttle (accelerator), transmission (gearshift), and steering.

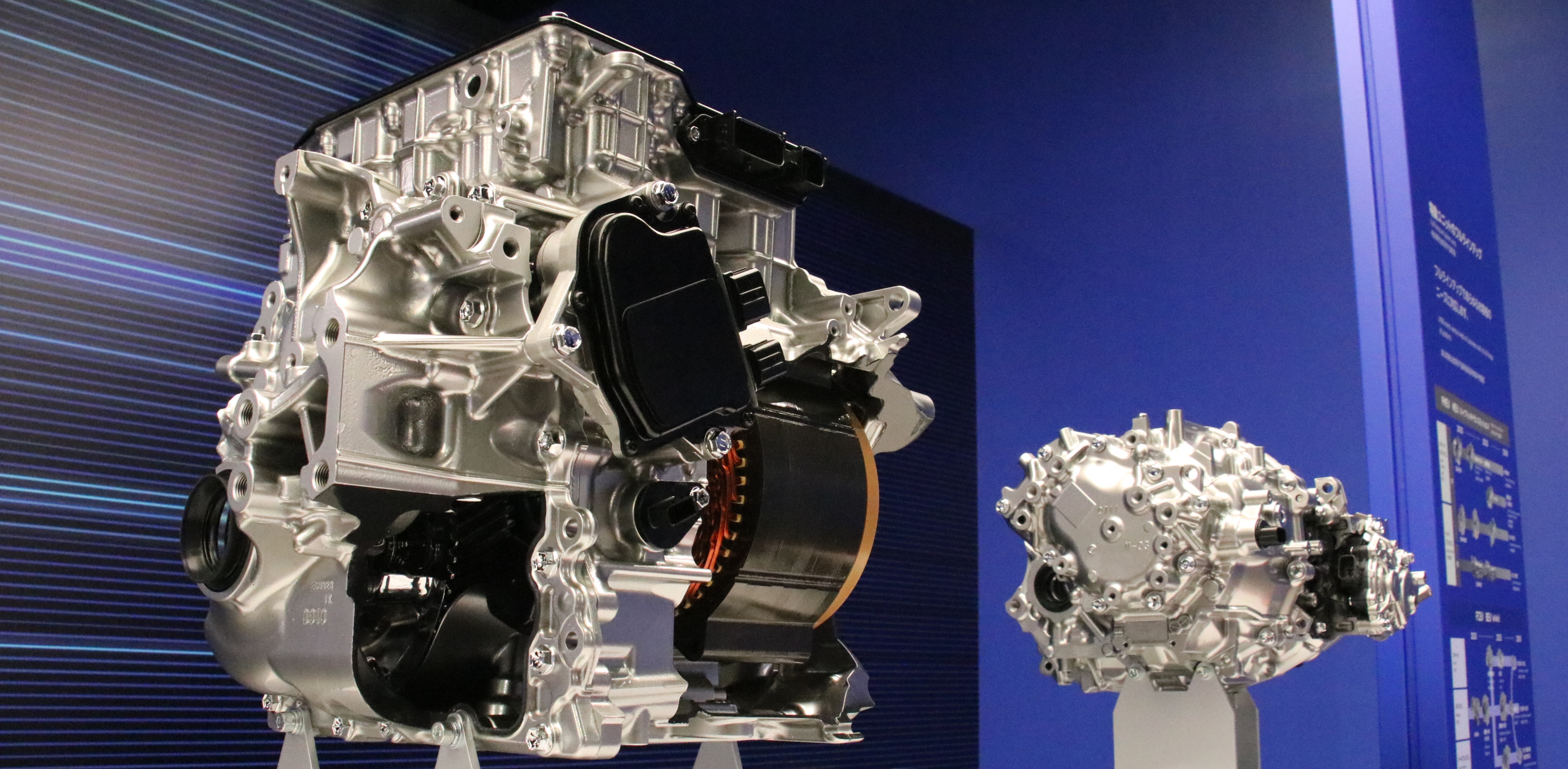

ADVICS, an AISIN Group company, is attempting to introduce this by-wire system into brakes via electric disc brakes. What was next unveiled was a Future Brake system that is planned to be introduced in Step 1. (See diagram) As a first step, only the rear wheels have been modified to electric.

The master cylinder, which controls the brakes, is mounted in the front of the vehicle. While the distance from the master cylinder to the front wheel brakes is short, the hydraulic piping to the rear wheels is long, a common vehicle design limitation. By making the rear wheels electric, it is possible to improve packaging versatility and reduce weight. In addition, the control range of the regenerative braking system is expanded, which also improves electricity efficiency. Eliminating the need for hydraulic oil also helps reduce the environmental impact.

The feel of the test vehicle brake was natural and not significantly different from hydraulic brakes. Meanwhile, the braking response seemed to have improved dramatically. It felt close to the figure published by ADVICS of “7% reduction in braking distance.”

Aerodynamic devices contribute to improving maneuverability and electricity efficiency

AISIN is developing aerodynamic devices attached to various parts of the vehicle body to improve electricity efficiency. This technology was also available to experience at the test drive event. The objective is to reduce aerodynamic drag while driving, and when all aerodynamic devices are in use, electricity efficiency is said to improve by an astounding four percent.

The front grille shutter closes when driving at high speeds. The movable spats in front of the tires, rear spoiler, and rear diffuser only operate when driving to streamline the incoming air. In contrast, door handles and other parts are only used when getting in and out of the car and are retracted in the vehicle body when driving because they cause aerodynamic drag.

With all devices turned on, I tried changing lanes quickly and experienced very smooth movement. Cornering at high speeds is also significantly stabilized, in fact the car’s behavior is so stable that you may want to go faster and further into the curves. When I think of aerodynamics, I imagine it contributing to electricity efficiency and straight-line stability, so I was surprised to find that the effect was most noticeable during cornering.

The parts of the vehicle shown in red (labels shown in blue) are the aerodynamic devices in operation.

Automatically predicts and slows down when approaching sharp corners

In the area of intelligence, technologies have been developed that go beyond simply obtaining information from moving vehicles to making full use of big data to improve safety, fuel and electricity efficiency. Using car navigation systems to warn drivers of dangerous areas where accidents are likely to occur is already common, but AISIN is also collecting and integrating huge amounts of vehicle and road data from the wide range of products that the group handles, including brakes, steering, drive units, and car navigation systems. The company is working on integrated vehicle control that manages each device according to the situation.

For example, when approaching a sharp corner on an unfamiliar road, a human driver will tend to drive too fast and apply the brakes heavily. By inputting road information such as the locations of corners into the vehicle in advance, the vehicle can automatically control and decelerate to enter the corner at the appropriate speed. On slopes, it is also possible to implement control according to the weight on each wheel.

When I used this system on the test vehicle, the car automatically slowed around sharp curves. Although it differs from what humans intend, it feels similar to engine braking or deceleration during regeneration, and it doesn’t feel particularly strange. If this technology becomes widespread, it will enable novice drivers to acquire the same skills as experienced drivers who can adjust their speed to avoid incident. In addition, smoother acceleration and deceleration also leads to improved electricity efficiency.

It is a very interesting system as a new approach to improving safety and electricity efficiency.

Stress-free entry with doors that open automatically

The intelligence of automobiles is now apparent both when driving and when riding in the vehicle. Technology like smart entry is now common, allowing most drivers to unlock and lock the vehicle by approaching it and touching the door – no key necessary. In addition, many vehicles are equipped with kick sensors that allow access to the luggage compartment.

AISIN is developing intelligent technologies that go even further than this. At the test drive event, the Stress-Free Entry System was unveiled, which automatically opens and closes the doors at the appropriate time, without the need for any operations such as touching the door.

This system requires advanced judgment skills to precisely detect people’s movements and determine whether they are simply approaching the vehicle or want to get in. The system must judge the user’s intention and open in a timely fashion, but also must ensure safety in the surrounding area as it opens. AISIN is well equipped to enter this domain that demands such high-level intelligent technology.

Similarly, door technology is rapidly evolving, and development is underway to adopt a novel front and rear linked door system. At first glance, the test vehicle appears to have sliding doors, but both the front and rear doors are designed to open and close using arms, and there are no rails on the sides of the vehicle. This means there are fewer restrictions on aesthetic design.

Like a sliding door, this structure allows the door to be opened and closed safely even in tight spaces and makes getting in and out smoother. The test vehicle is designed without the B-pillar between the front and rear doors, and if this is put into practical use, it will make it easier to get in and out of a variety of vehicles, regardless of model.

Unlike hinged doors, the front door moves sideways like a sliding door.

AISIN is simultaneously developing numerous electrification and intelligent technologies. When I actually test drove each of them in the technology and test drive experience event, it became clear that the progress of the development of these technologies is already close to that of commercialized vehicles.

The electrification of mobility will continue to advance worldwide. In this climate, AISIN is steadily moving toward a carbon-neutral future. As the parts manufacturer closest to automobile manufacturers, its role will become even more important in the years to come.