Report on Technology and Test Drive Experience Event: Electrification and Intelligence [Part 1]

- Remarkable new technologies at work at the vast Toyokoro Proving Ground -

Feb.10, 2025

![Report on Technology and Test Drive Experience Event: Electrification and Intelligence [Part 1]](/en/aithink/assets_c/2025/02/top_1001-thumb-4032x2015-9775.jpg)

As the automotive industry undergoes its biggest transformation in 100 years in pursuit of achieving carbon neutrality, it is essential to shift from engines that use fossil fuels (internal combustion engines) to motors powered by electricity, or a combination thereof.

However, it is not possible to replace mobility with battery electric vehicles (BEVs) entirely and all at once. A market in which various types of electric vehicles, including vehicles that use both engines and motors, such as hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs), coexist is expected to continue for some time.

AISIN is not only keeping up with this trend, but leading the effort. The company has strengths in transmissions, something BEVs no longer require. Therefore, AISIN is currently working on developing new products, including drive units for BEVs. This article delivers a two-part report by automotive writer Motoki Watase on his experience at a test drive event that introduced AISIN’s new technologies.

AISIN’s two pillars: electrification and intelligence

At the Technology and Test Drive Experience Event: Electrification and Intelligence held at the AISIN Toyokoro Proving Ground in Toyokoro-cho, Hokkaido in August 2024, the latest technologies currently under development were unveiled to members of the press and others.

The AISIN Toyokoro Proving Ground is one of the largest test courses in Japan, covering an area of approximately 768 hectares (approximately the size of 160 Tokyo Domes). There’s a wide variety of environments available, including circular tracks for high-speed driving, unpaved winding roads, and courses that recreate paved roads from around the world, as well as packed snow and icy roads in the winter.

AISIN is known as “the auto parts manufacturer closest to automobile companies.” The company doesn’t just refine individual parts to improve their performance and precision but also considers the impact on the vehicle as a whole and how it is possible to combine multiple parts to offer them as a unit. For example, when it comes to electricity efficiency, parts are developed from a holistic perspective, with an eye on how they can contribute to overall vehicle performance.

To achieve this, parts under development must be tested and evaluated while installed in the vehicle to ensure they can handle any situation the car may encounter, thereby improving the vehicle as a whole. In other words, the proving ground needs to be able to recreate a variety of different situations, such as paved roads, dirt roads, low-mu roads, gaps, and other road conditions, as well as traffic conditions such as highways and urban streets and weather conditions such as rain, snow, and ice. The Toyokoro Proving Ground can be said to be an indispensable and important site for realizing the technologies that AISIN is aiming for.

AISIN unveiled advanced development of technology based on its strategic shift of business to growth areas and strengthening the company’s foundation, which the company declared at the Medium/Long-Term Business Strategy Briefing held in September 2023.

The key areas of focus for AISIN are carbon neutrality, electrification, and intelligence – the three pillars. The technologies showcased at this test drive event were mainly those related to electrification and intelligence that are currently under development. First, in the area of electrification, technologies such as the next-generation electric drive module,* brakes, and aerodynamic devices were unveiled.

* It is envisioned that the module will be distributed through BluE Nexus, a joint venture of AISIN, Denso and Toyota.

AISIN is the only automotive parts manufacturer that offers a full line of drive units for BEVs, HEVs, PHEVs, and FCEVs (fuel cell vehicles). Furthermore, the company has a system in place that allows them to respond to all customer needs, including body size, drive system (FWD/RWD), and country-specific circumstances.

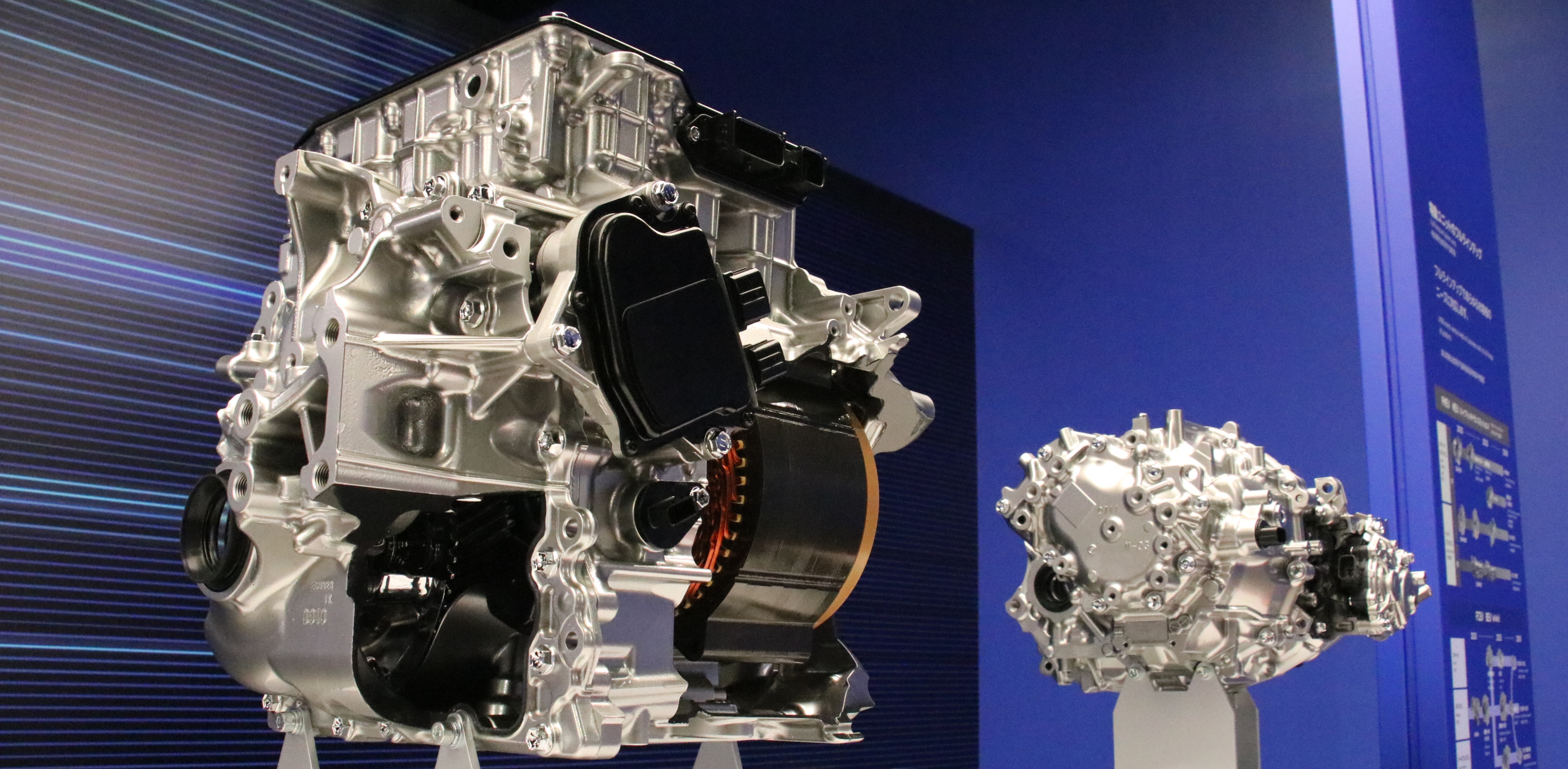

Next-generation electric drive module Xin1 eAxle

The eAxle is a combination of the inverter, gearbox and motor required for a BEV to move. AISIN is also developing the Xin1 eAxle, which combines multiple parts and functions into one.

The “X” in Xin1 indicates the number of integrated components. The model announced this time is a 9in1 eAxle that integrates nine components, including a power conversion module, thermal management device, motor and reduction gear. The Xin1 is scheduled to be introduced as the third generation eAxle, building on the success of its predecessors. Compared to mass-produced products, it occupies 60% less space, weighs 40% less, and has 50% less heat loss, resulting in significant improvements in space and energy efficiency.

It is planned to be launched for small-sized vehicle models. I test drove a vehicle equipped with the system at a maximum speed of 120 km/h on a course at the proving ground. Because it was a BEV, there was no excessive noise. The powerful acceleration that only a BEV can offer will likely make it easier to merge onto a main lane on a highway.

Making the drive unit smaller and lighter also gives greater freedom in vehicle body design. It allows for expanded interior space, creation of a crumple zone, or increased battery capacity to extend driving range. This unit is capable of meeting the various needs of automobile manufacturers.

New two-motor drive unit for HEVs/PHEVs

BEVs have been considered the trump card for achieving carbon neutrality, but issues remain regarding their convenience, such as the provision of quick-charging stations and the need to reduce charging times. Even so, the number of new BEV registrations is showing a slight upward trend, but the presence of more user-friendly HEVs and PHEVs (especially PHEVs, which can travel for longer periods on electricity) is growing rapidly.

Both HEVs and PHEVs are equipped with an engine and a motor, but their mechanisms differ depending on how they are used. There are a variety of different systems for HEVs in particular, including a system in which the engine is used only for generating electricity and driving is limited to the motor, known as the “series system,” and a system in which the engine and motor are used in an appropriate ratio for driving, known as the “split system.”

AISIN recently developed a system called the “series-split system,” which combines the best of both the electricity-efficient series system and the fuel-efficient split system. With the split system, energy loss occurs because the generator motor is rotated when the vehicle is traveling on motor alone. The series-split system separates the drive motor from the generator motor to prevent rotation, similar to the series system. This has improved the electricity efficiency when driving on the motor alone.

During the test drive, I tried to detect any small vibrations or strange sensations that might occur when the generator motor was disconnected, but to my surprise, I couldn’t detect any such signs at all. Other than a slight change in the sound, the unit had a very smooth feel.

The new system will contribute greatly to improving fuel and electricity efficiency not only in HEVs but also in PHEVs, which spend longer driving times in EV mode. Due to environmental regulations, the need is expected to further increase for PHEVs in large vehicle models in the future, and the need for new systems that contribute to driving performance and fuel and electricity efficiency will also increase.

In Part 2 of the report, I will describe new electrification technologies, including those related to brakes and aerodynamic devices, as well as those related to intelligence.