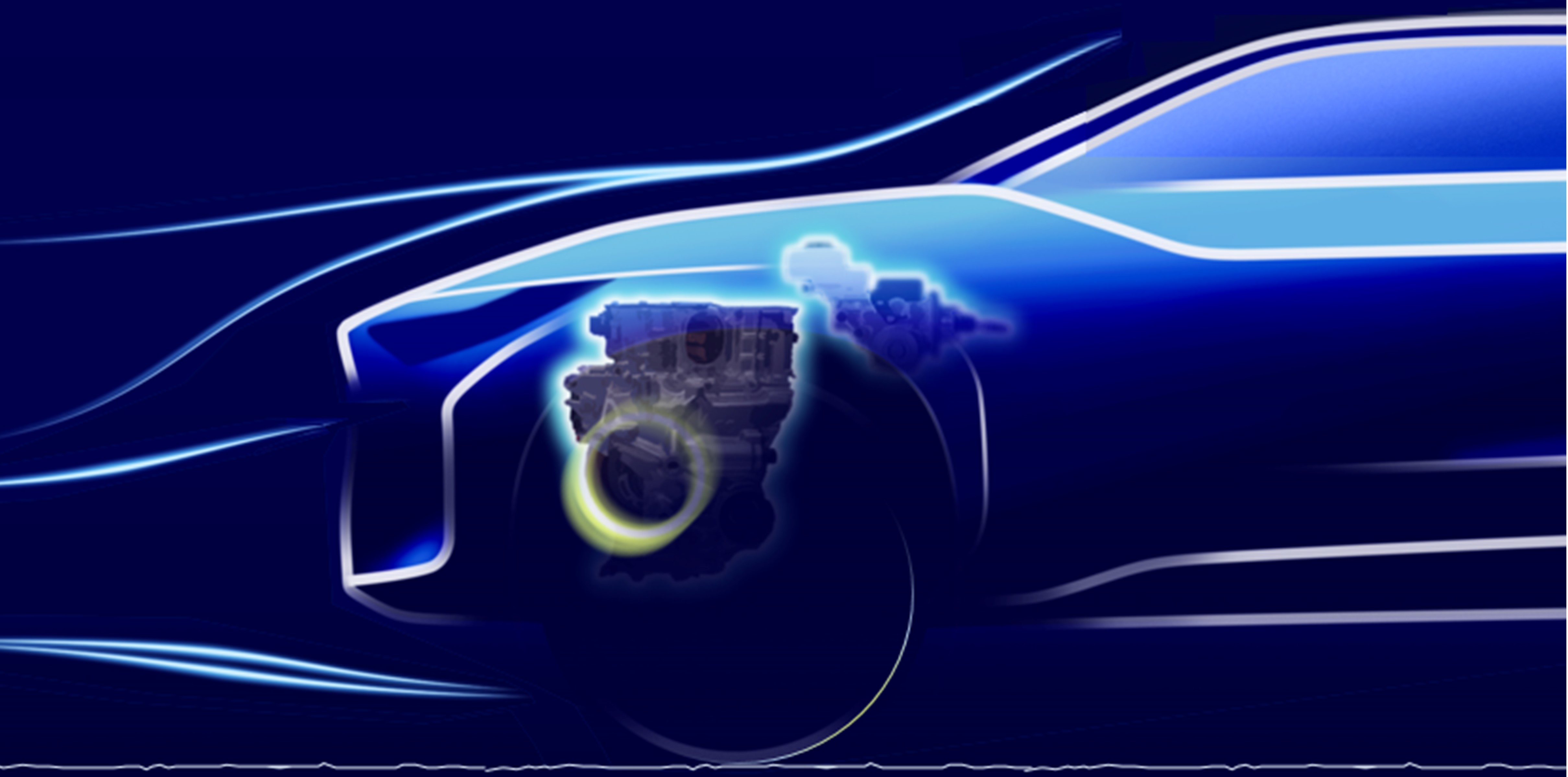

Aisin's central role in vehicle electrification

Jan.19, 2023

The world is rapidly moving toward carbon neutrality, and the electrification of vehicles, which helps reduce CO2 emissions, is playing an important part. Gasoline-powered vehicles have historically dominated the market, but battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs) powered by electric motors are becoming increasingly popular.

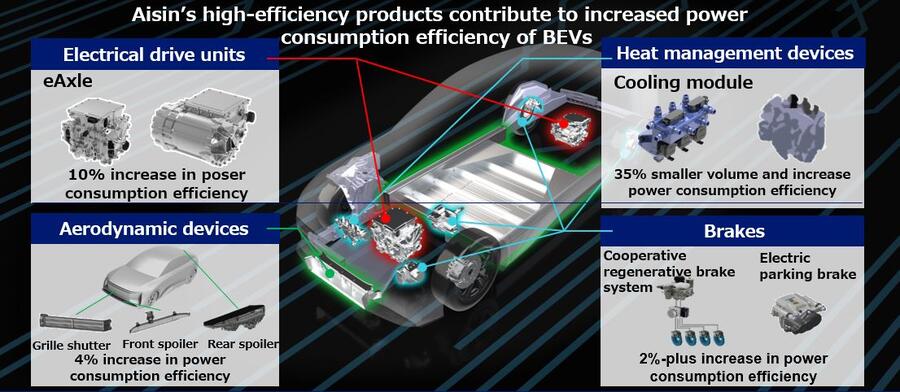

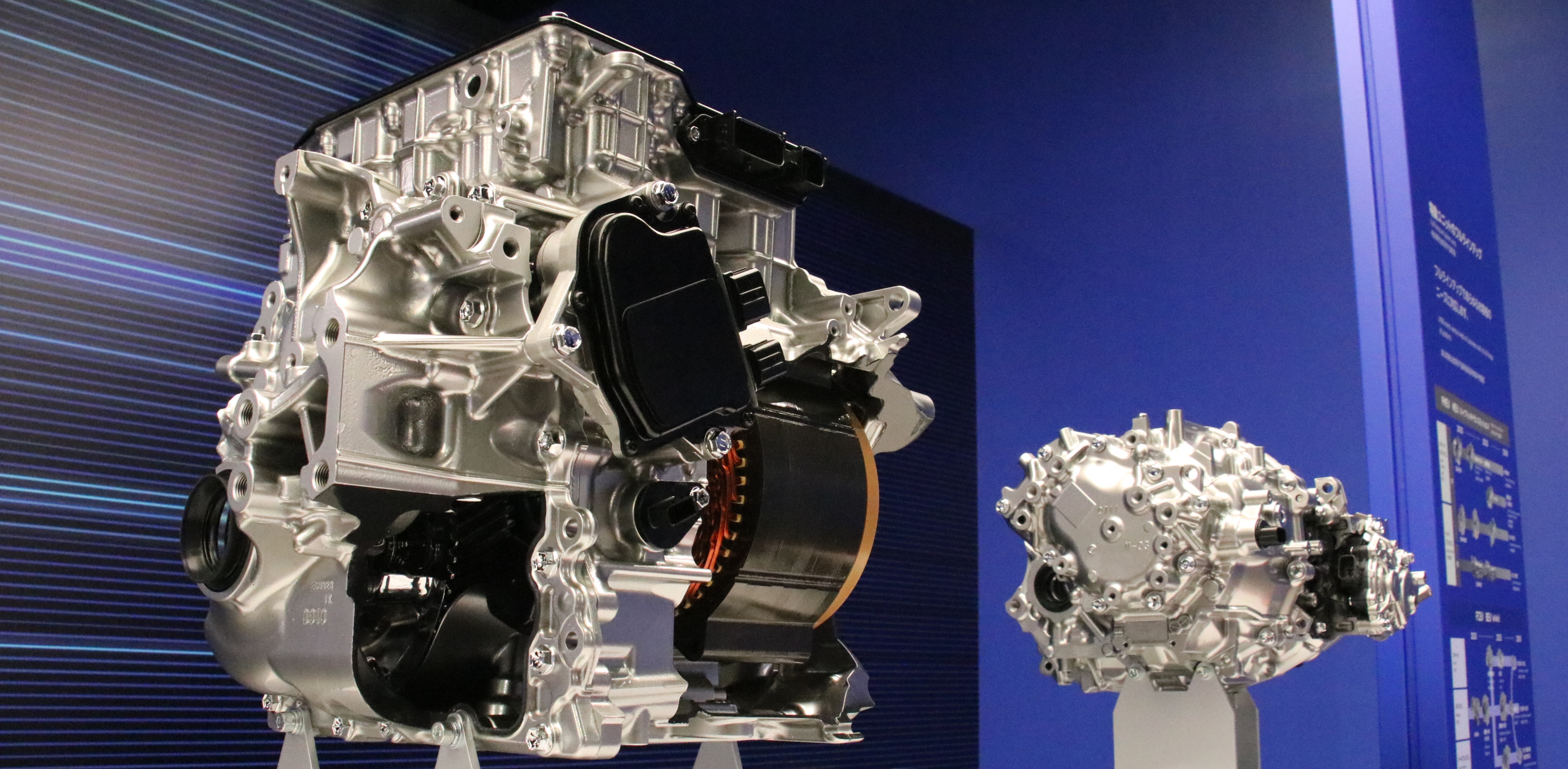

In light of these developments and in anticipation of rising demand, Aisin has positioned the eAxle - the driving force for BEVs as its most important strategic product. and is accelerating development in collaboration with BluE Nexus* and DENSO. Simultaneously, we continue to leverage our Group-wide experience in automotive components to develop a variety of products that improve the energy efficiency of electric vehicles.

* A company established jointly with Denso in 2019, specialized in the development, adaptation, and sale of electrification systems and electric drive modules (Currently, Aisin and DENSO each own a 45% stake and Toyota Motor Corporation 10%).

Broad range of products needed for BEVs

An important factor required for products used on BEVs is improvement in electric mileage because the electricity consumption rate is equivalent to the fuel consumption of engine-powered vehicles – and conservation is always key. If electric mileage is improved, the cruising range can be extended. With improved mileage range, vehicles will require fewer batteries, which allows for weight reduction, more effective use of interior space, and cost reduction. A combination of maximum power recovery and reduction of power consumption leads to a significant total effect.

Reduction strategies include: cooperative regenerative brakes, which efficiently recover energy while driving; cooling modules, which maintain optimal battery temperature and increase efficiency, and aerodynamic devices, which reduce air resistance during driving. These contributions to the improvement of electric mileage are wide-ranging and AISIN Group covers all the elements needed to electrify a vehicle with a wide range of product and technology lineups, including “battery peripheral parts” that ensure safety in the event of a collision.

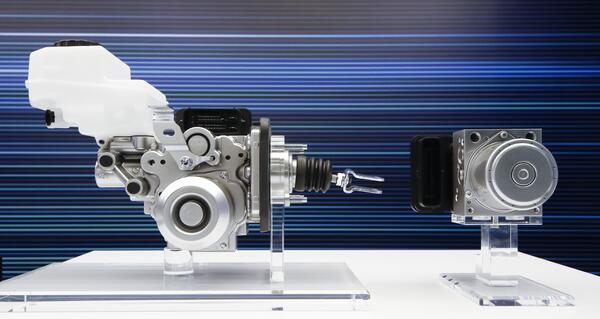

Cooperative regenerative brakes that reduce energy consumption

Regenerative brakes contribute to the effective use of energy while decelerating by recovering and capturing the vehicle’s kinetic energy as electricity. Cooperative regenerative brakes, in which both regenerative and hydraulic brakes are used with highly automatic control according to the required braking force, are used on BEVs and HEVs, and are developed and produced by ADVICS CO.,LTD. within the AISIN Group.

These products are already off to a great start in the market, as the system used in the Toyota bZ4X and the new Crown includes this function plus independent control of the front and rear wheel brakes. In conventional vehicles the same braking force was applied to all four wheels, but by separating the electronically controlled brake control system for the front and rear wheels, regenerative brakes are used more frequently, further improving electricity mileage while still providing a comfortable ride.

We will continue to expand our lineup for vehicles of various sizes and deliver optimal systems to even more customers together with electric units.

Related article

Stopping is Just the Start of what These Brakes Can Do | AI Think - Learning Aisin’s Now and Future

“Cooling modules” that control heat and increase efficiency

Like gasoline engines, BEV batteries, motors, and the inverters that control them all require temperature control to ensure stability and high performance.Proper temperature control can contribute to battery life, power stabilization, and efficient charging and discharging.

The heat-generating motor has passages for cooling oil, and the inverter and battery have passages for water. An Aisin electric pump pushes oil or water through these passages to provide cooling. Moreover, the valves used to control the flow of water are well refined Aisin products derived from our cumulativeexpertise. In the future, we plan to combine them into a single unit and integrate the functions into a single module, rather than installing them individually. That level of expertise and efficiency is only possible because Aisin handles a such a vast range of product groups. We will play an integral role in higher efficiency and downsizing required for BEVs, thereby contributing to the overall improvement of electric mileage.

Aerodynamic devices that contribute to electric mileage

When you think of “aerodynamics” controlling air flow, you may imagine a sleek sports car. However, all kinds of vehicles, including SUVs and minivans, can greatly improve electric mileage if they can soften the complex airflow (resistance) that occurs while driving.

Aisin has developed several aerodynamic devices, many of which are already being mass produced. One is the grill shutter, which is installed on the air intake area at the front of the vehicle. When the main components are sufficiently cooled, closing the shutter improves aerodynamic performance and contributes to the improvement of electric mileage. The other is the active front spoiler, (pictured below) which not only enhances the rectification effect during high-speed driving, but also contributes to quietness and straight-running stability. We plan to install them in various electric vehicles.

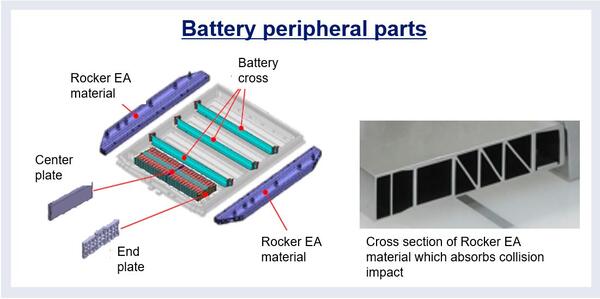

Battery peripheral parts that protect the energy source

A battery is essential to a BEV. Most batteries, which have evolved rapidly and become smaller and lighter, are commonly installed under the floor of a car. This location is likely to be protected from forward and backward collisions, just like the cabin space that protects lives. But batteries also need to be protected due to their necessity and cost, and also because a damaging impact on a battery could cause a fire.

AISIN KENKINZOKU Co., Ltd. heads the aluminum die-cast parts and aluminum extrusion parts business for automotive application within the AISIN Group, and produces Rocker EA (Energy Absorption) cushioning material to protect batteries.. In the event of a side collision its “ladder cross-sectional structure” (pictured) effectively absorbs the impact, then it deforms to minimize damage to the battery. The Rocker EA is already installed on Toyota bZ4X.

We apply technologies that we’ve cultivated in the manufacturing of lightweight aluminum components and in downsizing and weight reduction of door frames and other body parts to the creation and manufacturing of various electrification products.