DX Changes Production and Human Resources

—Hands-on Learning To Create Confidence And A Challenge-Oriented Mindset—

Aug.05, 2022

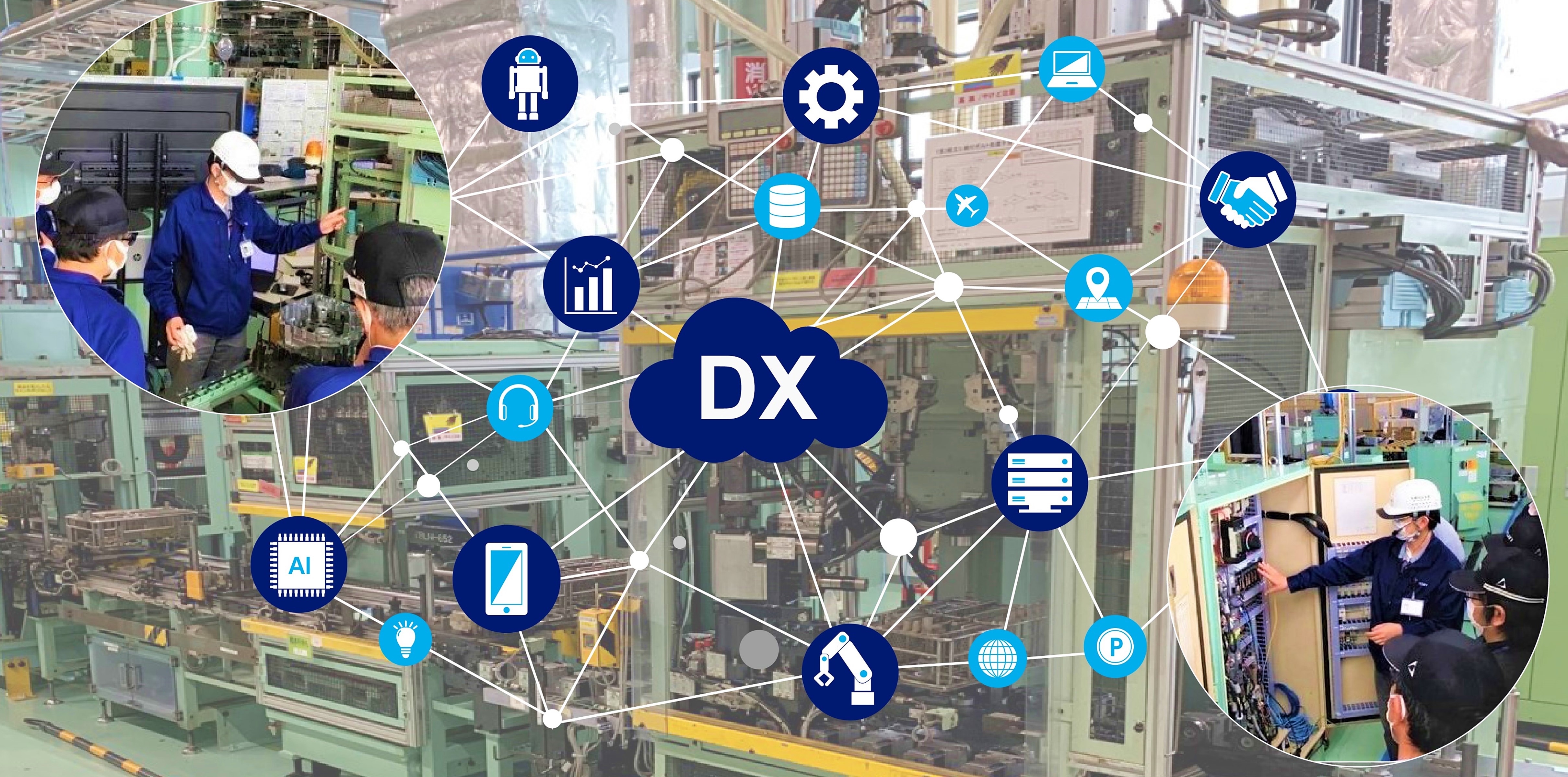

At Aisin, we have been actively working on DX (digital transformation) in manufacturing to quickly respond to diversifying market needs and to make an impact on social issues.

The automobile industry is going through a once-in-a-century period of great changes. For survival and further growth, it is important that we evolve manufacturing outside of conventional methods and create new value for our customers and for the world.

As a “Cyber-Physical Information Factory,” we have been striving to reform our business and make necessary transformations in manufacturing through the power of digital technology.

An often-overlooked component of DX are the individuals that create and monitor the DX process – our valuable human resources. Now more than ever, we need to identify, train and develop team members who are able to handle continuous change and make full use of the digital tools required in the manufacturing field, including IoT and AI.They also must continuously monitor and carry out reforms.

Aisin’s DX human resources development

DX means to reform processes, organizations, and business itself by utilizing digital technology.

There is no better place to start than with the person who is engaged in the task and deeply understands the issues related to the task and the team. These individuals will take a lead role in the reform and will advance the activity as his or her own issue.

Aisin has been promoting acquisition of digital skills and their utilization in business on a company- wide basis, not just for workers involved in manufacturing. We offer training regardless of job type or position under the basic policy of “DX involving all employees,” where each worker strives to become a person who is capable of correctly understanding and utilizing digital technology to create new value in their own unique way.

Hands-on learning of digital technology

Most work reforms at production sites have been conducted separately by specialists within the fields of their specialty. For example, production technicians and plant workers improved and reformed production equipment and processes, while IT team members improved and reformed computer systems. To accelerate work reforms through DX, however, shop-floor workers who promote improvements and reforms at the front line of manufacturing also need to understand a series of digital technology utilization processes.

Therefore, Aisin has been focusing on hands-on training with an environment similar to actual mass production lines while giving classroom training to acquire knowledge of the digital technologies required for production.

Educational production line to learn about digital technology utilization in the manufacturing field

In 2022, we set up an educational production line that enabled trainees to learn about IoT, which is the basis of digital technology utilization at production sites. We will further develop a learning setting where employees can acquire practical know-how in an environment that is as close to the reality as possible.

“Dream Plant TUNAGU,” a mock production line for digital technology training

The planning and operation of the educational production line is promoted by a working group consisting of staff members from various departments, including Plants, Production Engineering, Human Resources Development, and DX Promotion. The working group takes in the opinions of shop-floor workers and devises training that reflects diverse perspectives.

With the goal of fostering a mindset that actively takes on challenges, the mock production line enables trainees to learn about a series of processes required for the utilization of IoT, including data acquisition, accumulation, and utilization. They also get to try out equipment and systems and apply what they have learned in classroom lectures to build real experience.

Scenes from training

A challenge-oriented mindset is key to promoting Aisin’s DX. Training that simply increases knowledge does not offer practical experience or insight. Such training alone is not enough to support the first step toward working on DX.

The educational production line enables trainees to experience software and equipment and gain experience by repeated trial and error. This hands-on experience them self-confidence and motivates them to take action in the real environment, too. Using the educational production line as a starting point, we will continue to build a culture that encourages employees to address DX.

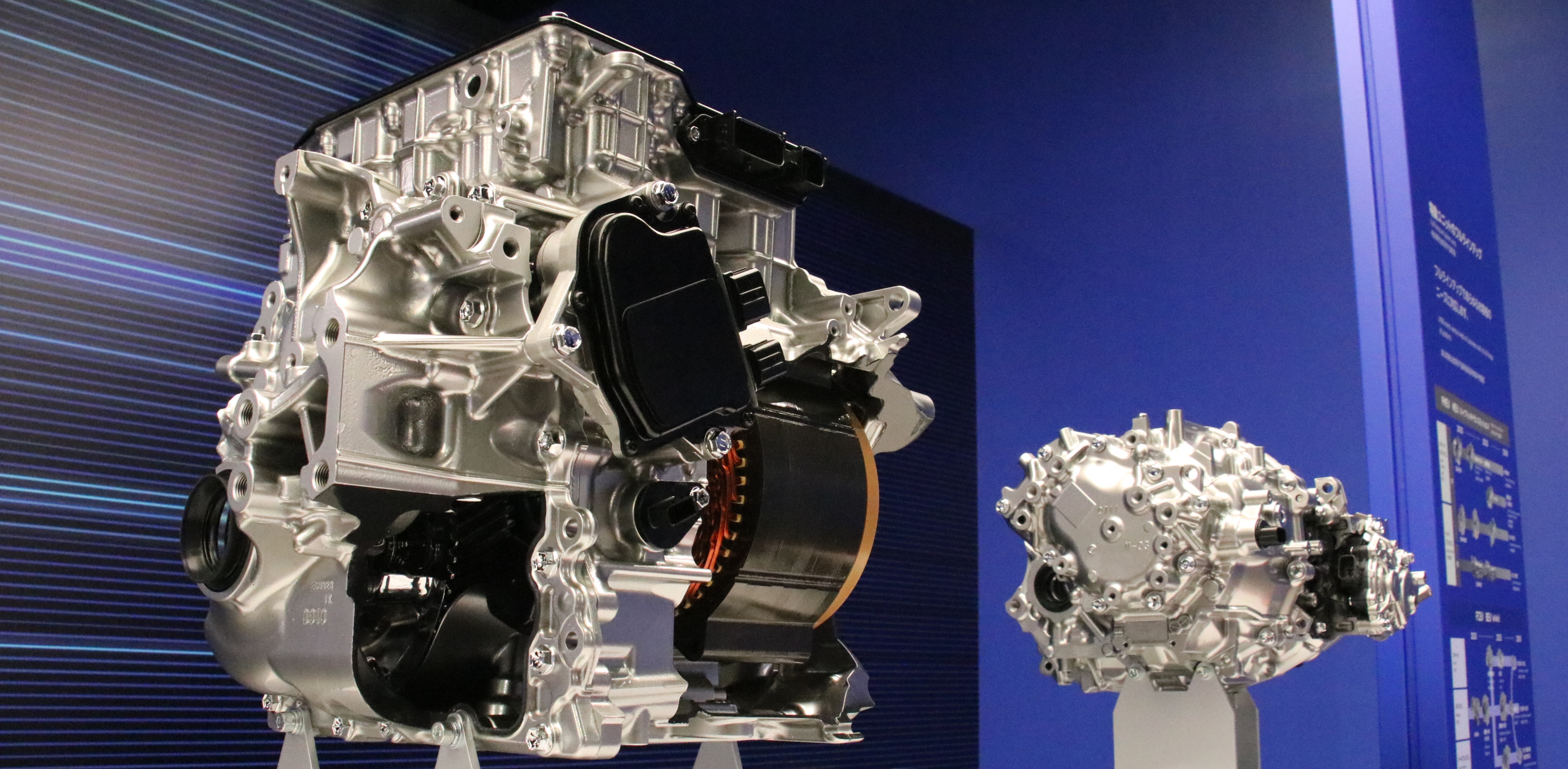

The current educational production line is geared toward drive units, but we will expand and improve the environment and system to offer training that covers Aisin’s wide range of products. The ultimate goal is to have each of our plants operate at a level where they are each capable of pursuing DX in a responsible way based on their own ideas.

A culture and spiritual climate of “Kaizen,” a Japanese concept that refers to continuous improvement, has already taken root at Aisin. By adding knowledge and awareness of digital technology and instilling employee confidence in the technology, we will accelerate our efforts toward DX resulting in higher quality, more efficient production, lowered costs and the creation of new value.

The current educational production line is based on the processing and assembly lines of drive units. To offer training that covers Aisin’s wide range of products, we will improve the training environment and system. We will accelerate our efforts with the aim of raising all our plants to a level where each plant is capable of pursuing DX in a responsible way based on its own ideas.

Staying committed to DX training of human resources who support our production sites, we at Aisin will support and promote their active efforts for reforms. Through innovative manufacturing, we will also contribute to building a future where everyone can feel safe and comfortable.