Using Methods of the Past to Solve Modern Day Problems: Aisin Applies Ancient Japanese Technology to New Models of Toyota Noah and Voxy

May.31, 2022

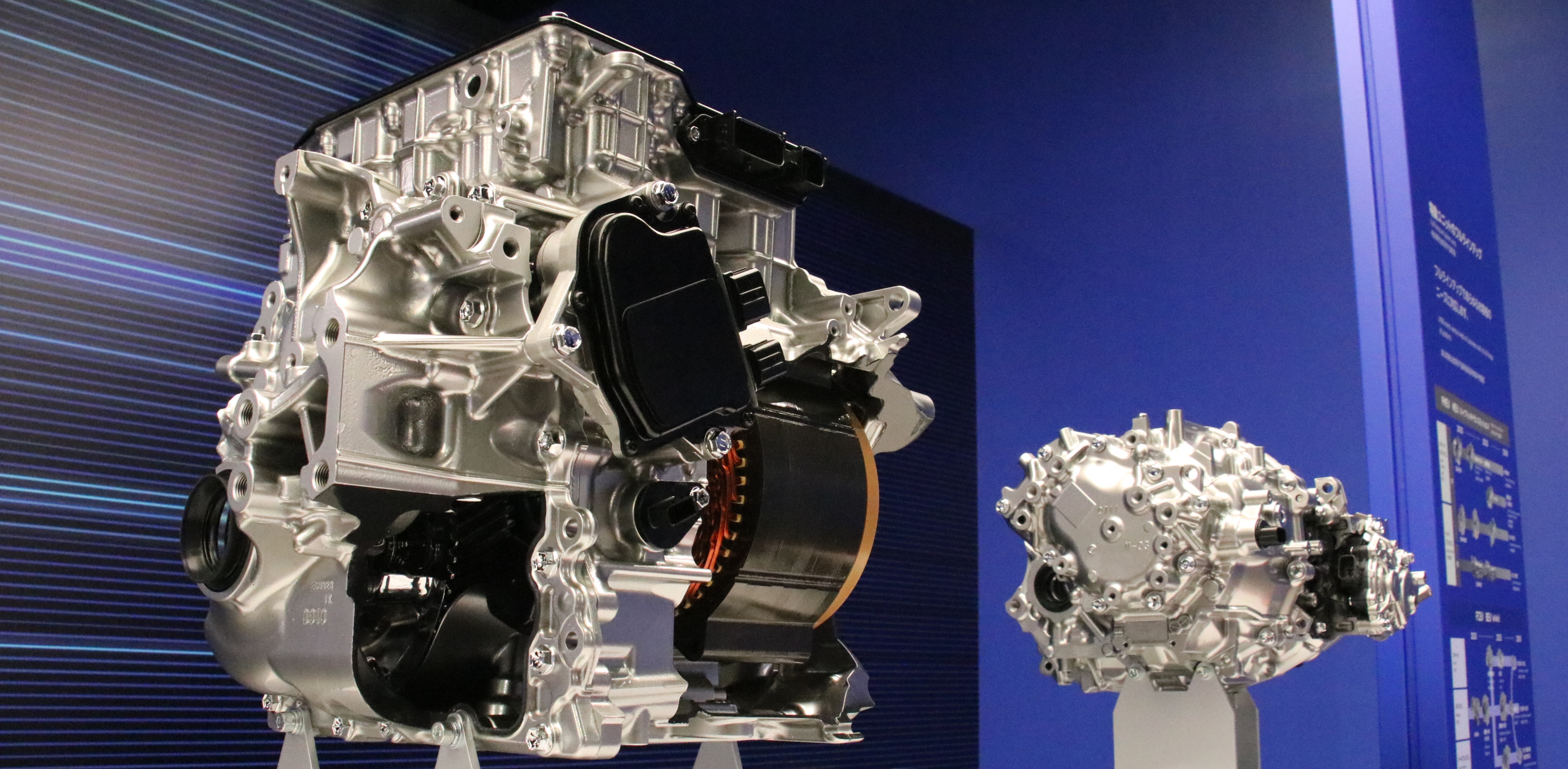

Aisin’s mission is to protect the planet while also bringing freedom and happiness to the concepts of movement and mobility. Through product development using automobile electrification technologies such as eAxle and advanced digital technologies such as AI, Aisin has offered a variety of innovations that directly contribute to a better society.

While most companies tend to highlight their modern and sophisticated technologies, Aisin honors the deep roots of an ancient system that still support its innovations.

Aisin has actively applied technologies inspired by karakuri,*1 a time-honored Japanese mechanical system, to its production activities. This simple mechanical system consists of gears and springs that make the device operate. An example of karakuri would be a delivery cargo carrier driven by the power provided only by a wind-up spring. The great thing about karakuri is that it doesn’t require expensive parts, such as a motor or a controller, nor does it use any energy resources, such as electricity or petroleum.

This “carbon-free” technology is easy on the earth as well as the budget.

Aisin’s new “Universal Step” and “Free Stop Back Door” products are epoch-making in that they solve drivers’ everyday issues using karakuri. We had the opportunity to interview the developers of these products, which have been adopted by Toyota for the new Noah and Voxy models.*2

*1: Refers to a time-honored Japanese mechanical system that moves an object using an elaborately crafted mechanism with threads, wind-up springs, and hydraulic power

*2: Released by Toyota Motor Corporation in January 2022

Universal Step uses karakuri for easier vehicle entry and exit.

Aisin’s Universal Step emerges from under the sliding door when the door is opened, and retracts when the door is closed. This step is designed to be about 20 cm above the ground, making it easy for passengers with any level of mobility - from children to the elderly - to get into and out of the car.

Keisuke Nomura, in charge of the development of Universal Step, talks about the potential of this product.

Q: Electric steps for getting into and out of a car are usually used for specialized mobility vehicles, aren’t they?

Nomura:

That’s certainly true. Since Noah and Voxy are family cars, their vehicle height is set relatively low. Even so, they are too high to enter and exit for elderly people who cannot raise their feet high enough and or for small children. In market studies, families with aging seniors or young children favor having a step in the vehicle and it has become an in-demand accessory for specialized vehicles as well as individual or family cars. However, conventional electric steps are costly because they require expensive parts such as a motor and a controller. Since cost directly affects price, cost reduction is the key to offering a more affordable product for wider customer base. So, we started developing Universal Step as a low-cost option to provide easy mobility to all passengers.

Q: How did you overcome the cost problem?

Nomura:

Conventional electric steps require dedicated parts like controllers and motors for pulling the steps out and back in. These parts increase the overall weight and volume, and thus the price. Aisin’s Universal Step extends and retracts when the door is opened and closed. This operation is enabled by a combination of karakuri and Aisin’s Power Sliding Door, a product that boasts the world’s top-class market share.

Its simple structure and its use of zero electricity has enabled Universal Step to achieve a much lower cost than electric steps.

I believe that this development project succeeded because all the members worked as one with a passion for creating a useful product. We will continue to strive for product development that provides comfort, safety, a clean environment and mobility for all.

Free Stop Back Door is the world’s first rear door that can be held at any desired angle.

Aisin’s Free Stop Back Door is the world’s first*3 rear door for minivans, such as Noah and Voxy, that can be held at any desired angle. This product is another example of cost reduction achieved with a karakuri mechanical system.

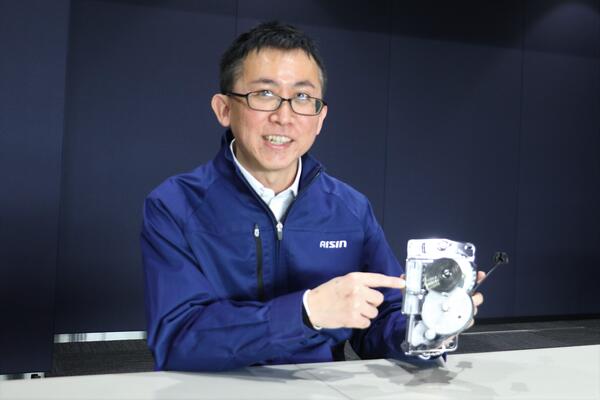

Takayuki Fukuda, in charge of the development of Free Stop Back Door, talks about the details.

*3: According to Aisin’s research

Q: In a small parking space at a supermarket, I often find it hard to open the rear door of my car.

Fukuda:

I know what you’re saying. When you park in a narrow space, there may be a wall or pillar so close that you cannot open the rear door to load luggage into the trunk. Or, when you fling the rear door open, it may open at such a wide angle that you cannot reach the door to bring it down. So, we have devised a new mechanism that enables you to hold the rear door at any desired angle.

Takayuki Fukuda, Development of Free Stop Back Door

Q: How does that differ from a power (electric) rear door, which opens and closes automatically?

Fukuda:

Power rear doors can be easily opened and closed with a button in the car or a remote controller. They can also be held at any angle. The convenience of opening and closing them with the touch of a button is so great that power rear doors will presumably remain mainstream. However, since they use an electric mechanism, a motor and an electronic substrate need to be mounted, which inevitably increases the weight and cost. Our Free Stop Back Door doesn’t require any of that and instead provides easy manual handling and low cost because it employs a karakuri structure to operate without electricity and hold any desired angle.

Q: That technology is the first in the world, I presume. Could you elaborate on that?

Fukuda:

The most helpful thing about Free Stop Back Door is that it can be held at any desired angle. To make this happen, we have devised a structure that combines the retractable mechanism of ballpoint pens (a click pushes the tip out, and another click pulls it back in) and a torque limiter mechanism (which interrupts the transmission of force). An intermediate stopper is connected to the rear door with a cable, which enables you to lock/unlock the cable by pushing the door and hold the door at the desired angle.

To this structure, we have added a clutch mechanism to prevent the door, when slightly open to load or unload luggage, from being damaged due to an overload accidentally applied by the head or back of the user. None of these require an electrical mechanism, they instead combine the karakuri mechanical system and our experience with existing products.

An electrical mechanism is used for almost every modern vehicle system today. So, it was quite a novel idea to develop such a simple, karakuri-based system. This would not have happened without our strong commitment and determination to anticipate and service our customers’ needs.

Making full use of all the technologies and experience it has gained, Aisin will continue to anticipate and exceed the needs of our customers in the best possible way, bringing freedom and happiness to “movement.”