Aisin's "e-Four" Conducive to Comfortable, Worry-Free Driving

A powerful electric 4WD unit that exceeds expectations for new minivans

Apr.28, 2022

Mid-sized minivans are favored by families but aren’t often known for being high-performance or fun to drive. Toyota's recent revamp of the Noah and Voxy is likely to change that. The first full model change in eight years took place in early 2022 and included the addition of four-wheel drive (4WD) specifications that were absent in previous-generation hybrid electric vehicles (HEVs). Because of these upgrades, Toyota is already gaining minivan market share.

Noah and Voxy, which are basically front-engine, front-wheel drive(FWD) employ the same body design as 4WD vehicles. Their luxuriously spacious interior has a flat floor, providing generous legroom for rear seats and a “super luggage box” with ample storage under the luggage compartment floor in the rear.

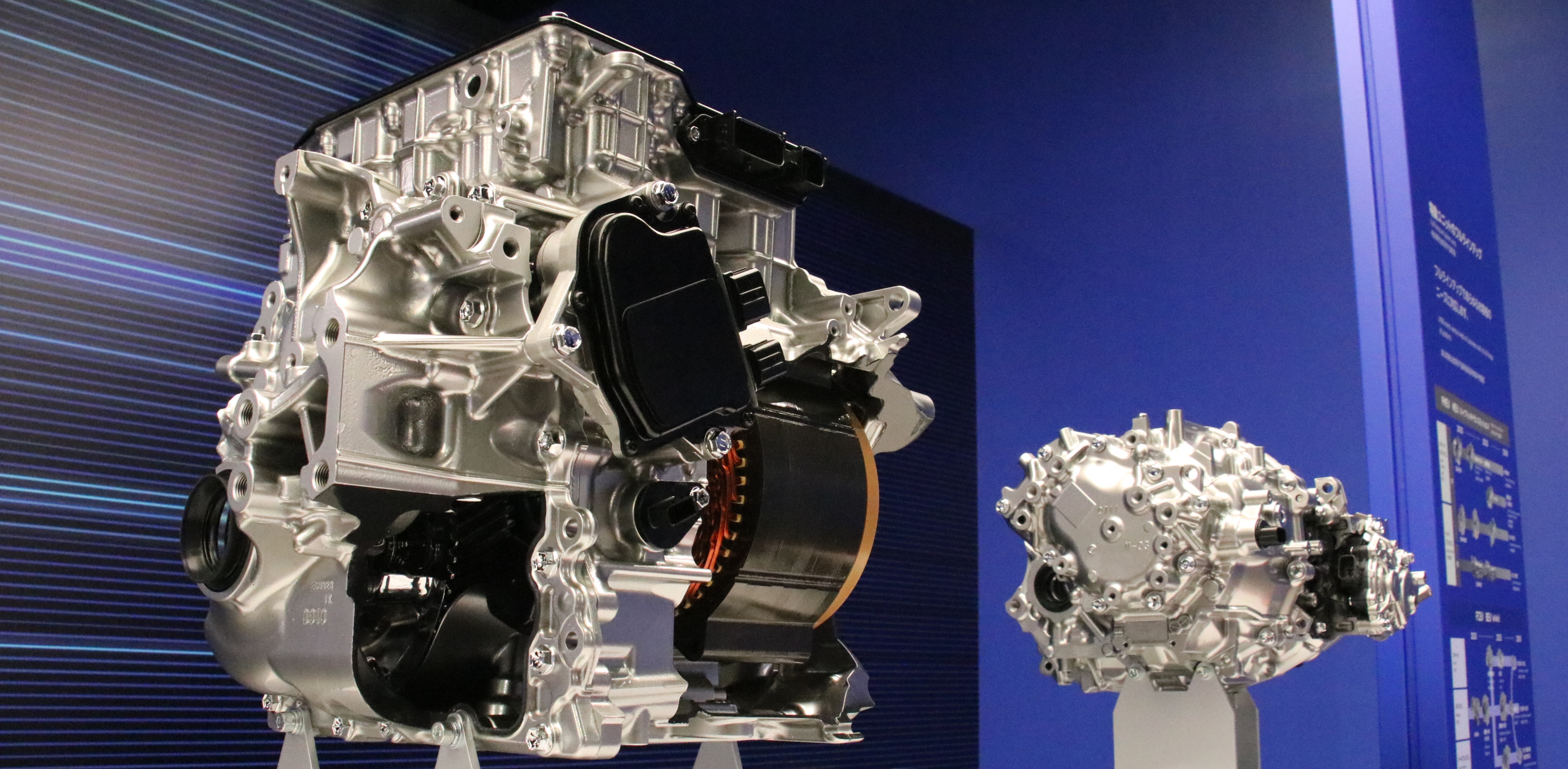

The achievement of excellent driving performance without sacrificing interior space - even for HEV 4WD models - is largely attributable to Aisin’s newly developed electric 4WD unit (e-Four).

The magnitude of its evolution cannot be underestimated

The first thing that comes to mind when you hear the term “4WD” is a vehicle navigating icy streets or an off-road SUV. However, to the delight and safety of consumers, 4WD systems are now installed in various vehicles, including sedans and minivans.

In traditional electric 4WD systems, a front-wheel-drive vehicle is supplemented with an electric motor for rear-wheel drive. The vehicle is automatically switched to 4WD only when driving on snowy, uphill, and other slippery roads. The speed range covered by this electric motor for rear-wheel drive is generally up to about 30 km/h at best. The motor provides no more than a start-assist function.

Aisin’s newly developed e-Four changes this paradigm completely.

Surprisingly, the maximum output and torque of the new e-Four are 30 kW and 84 Nm, respectively. Those of our conventional products installed in the Prius 4WD model released in 2016 are 5.3 kW and 55 Nm. Comparitively, our newly developed e-Four can produce about 5.7 times higher output and about 1.5 times higher torque.

To put it another way, it has the power performance comparable to that of a Japanese microcar solely for rear-wheel drive.

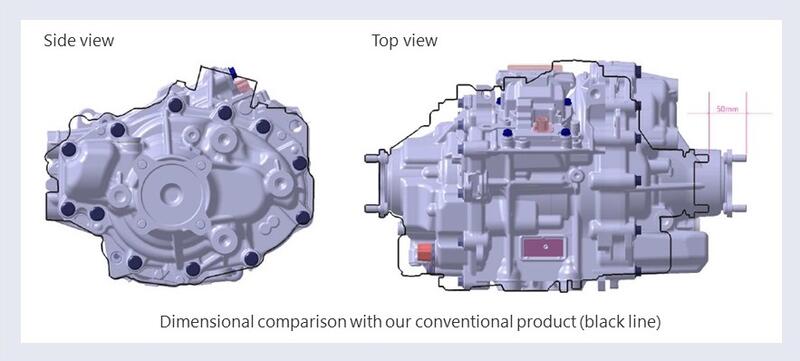

Pursuit of compact design

In simple terms, to obtain high power, we apply a large current to a large motor. However, a large, heavy unit would hinder Noah and Voxy from providing ample cabin space. In the development of the new model, it was required to fit into a compact space.

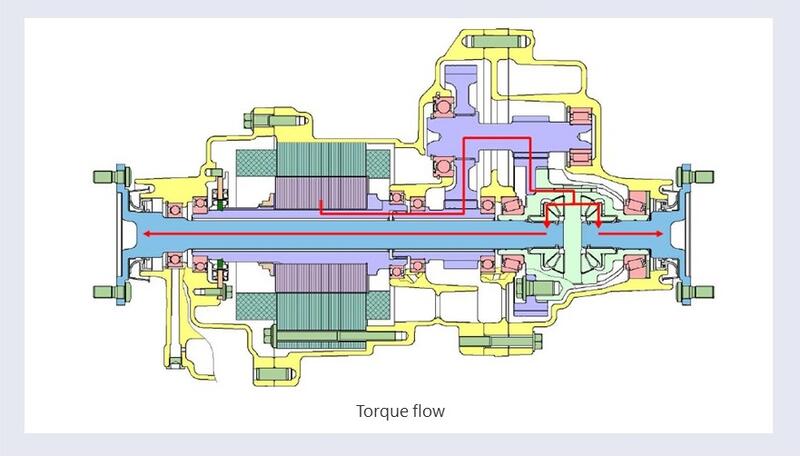

The key to success for this unit is the establishment of a two-shaft structure through adopting an interior placement magnet (IPM) motor and incorporating a double reduction gear. (See details shown in the structural drawing.) An IPM is used for the rotor of the motor. The input shaft through which the power of the motor is transmitted has a hollow structure, allowing the output shaft to pass through it. Generally, the medium of a transmission gear requires a three-shaft structure. However, the coaxial layout of the two shafts provides a compact design with excellent mountability.The result is the birth of an unprecedented electric 4WD unit, the new-generation "e-Four," without sacrificing comfortable cabin space of Noah and Voxy.

Improving dynamic performance and maneuverability

The e-Four unit is automatically controlled in coordination with the newly developed 1.8-liter hybrid system. When starting, e-Four allows the vehicle to transform into 4WD, enabling the four tires to grip the ground securely and help improve acceleration performance. Providing a powerful driving force through high speed ranges, the e-Four unit can demonstrate high performance close to full-time 4WD.

In addition, the driving force is appropriately distributed to the front and rear wheels according to the driver’s steering operation; and e-Four also helps improve cornering stability.

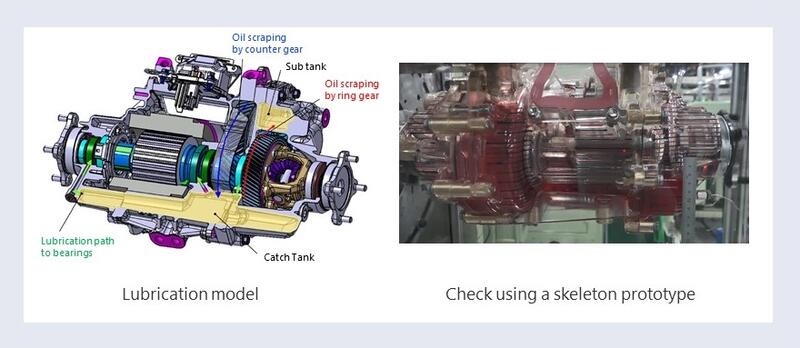

Mr. Kida, who leads the development of this new e-Four unit, commented on loss reduction.

"We employed our ingenuity in making each rotating shaft and gear, which transmits motor power, move as smoothly as possible,” said Kida. “In response to the power increase, we pursued higher efficiency in the oil-lubrication system in addition to increasing the casing stiffness.

“Oil is essential to prevent the seizure of gears and bearings, whereas it also causes loss due to viscosity resistance,” he continued. “To reduce loss to the extent possible, we put our knowledge and state-of-the-art technology that Aisin has cultivated into development.We have minimized the amount of oil necessary and installed channels where needed to guide the oil appropriately. Furthermore, we have newly adopted low-viscosity oil for hybrid products.

“While utilizing computer simulation technology, we spent a large amount of time testing actual systems, including skeleton models. We repeated thorough verification by, for example, observing the state of lubrication through windows installed at key points, thereby having achieved a highly efficient design with little loss, Kida concluded.”

To promptly respond to the various needs of our customers around the world, Aisin strives to provide electric units for all types of vehicles, including HEVs, plug-in hybrid, electric, and fuel cell vehicles. With the wide range of expertise we have cultivated over many years and our insatiable quest for the development of new technologies, we will further accelerate the electrification of vehicles.