Aisin's Technological Development Using Hydrogen

-Efforts to Ensure Earth’s Vibrant Future

May.25, 2023

Do you know what the most abundant element in the universe is? The answer is "hydrogen," and it is so important that it was deemed #1 (literally) on the periodic chart.

Efforts to utilize hydrogen as an energy source are attracting worldwide attention. In fact, Aisin was one of the first to focus on hydrogen energy and has been working on the development of fuel cells, which generate electricity using hydrogen as fuel, for more than 30 years. Hydrogen utilization holds the key to creating a carbon-neutral society which is a critical global challenge.

Here we will cover the basics about hydrogen utilization and Aisin’s unique approach to the shift in using hydrogenfor energy.

Why is hydrogen attracting attention?

At the Tokyo Olympics and Paralympics held in the summer of 2021, a torch fueled by hydrogen was lit for the first time in the history of the Olympic Games. Fuel cells (FCs), were used not only in vehicles used for the operation of the Olympics but also for the electricity and air conditioning of the athletes' village. In doing this, Japan sent a clear message to the world about its intent to create a hydrogen-based society. With the advent of Toyota's fuel cell vehicle, the MIRAI, and the growing popularity of household fuel cells hydrogen has become a common household name.

Since electricity is difficult to store in large amounts, it is important to balance its production and consumption. Natural energy using sunlight and wind power is difficult to control because its output varies depending on weather conditions. In contrast, hydrogen can be made from various substances on the earth. As long as hydrogen is available, FCs, which generate electricity through a chemical reaction between hydrogen and oxygen in the air, can be used to generate electricity at any time.

When hydrogen gas is sent to a FC, hydrogen molecules react at the negative electrode and separate into hydrogen ions and electrons. Hydrogen ions move to the positive electrode through the electrolyte (a special film called “solid polymer membrane”), and electrons are extracted as electrical energy and flow to the positive electrode. At the positive electrode, oxygen molecules supplied from the outside receive the electrons and become oxygen ions, which combine with hydrogen ions to form water.

The only emission after the output of electricity: water. Since FCs do not emit carbon dioxide and environmental pollutants, hydrogen is expected to make a significant contribution to the realization of carbon neutrality as the "ultimate energy source."

Aisin and hydrogenーA relationship that started in a tiny garage

Aisin's history of hydrogen-related product development dates back more than 30 years. At that time, many discussions were arising about problems with fossil fuels such as petroleum and natural gas, namely, concerns about their depletion and the emission of carbon dioxide, which promotes global warming. In 1991, Aisin started research and development of fuel cells for automobiles, believing that a hydrogen society will emerge in a hundred years due to the depletion of fossil fuels.The project started with three researchers in a tiny garage. With limited equipment and budget, the researchers learned about fuel cells from scratch and devoted themselves to the development of electrolytes (solid polymer membranes) and reformers.

Aisin continued the development of key components of fuel cells, such as battery stacks and fuel reformers, and built a new testing facility at the Fujioka Proving Ground (Toyota City, Aichi Prefecture). In 1998, a long-awaited methanol reforming fuel cell vehicle was developed in-house and tested.

Around 1999, the Toyota Group began full-scale fuel cell development. The fuel cell electric vehicle (FCEV) that was released in limited numbers by Toyota Motor Corporation in 2002 was equipped with many auxiliary parts developed by Aisin, such as control valves for the hydrogen and air supply/exhaust systems and humidifiers.

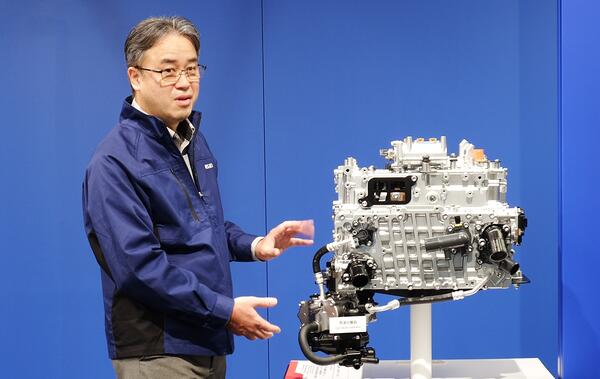

"I believe that Aisin’s early start of fuel cell development focusing on technology rather than products in anticipation of the advent of a hydrogen society greatly contributed to Toyota’s FCEV development,” said Katsuhiro Kajio, an engineer who was one of the early members of the fuel cell development team and is now in charge of the development of FC stacks and auxiliary equipment parts,. “In 2014, when the MIRAI was unveiled as the world's first mass-produced FCEV in a spectacular way surrounded by an audience, I was overwhelmed with memories of the past." said Kajio.

Aisin products used in FCEVs

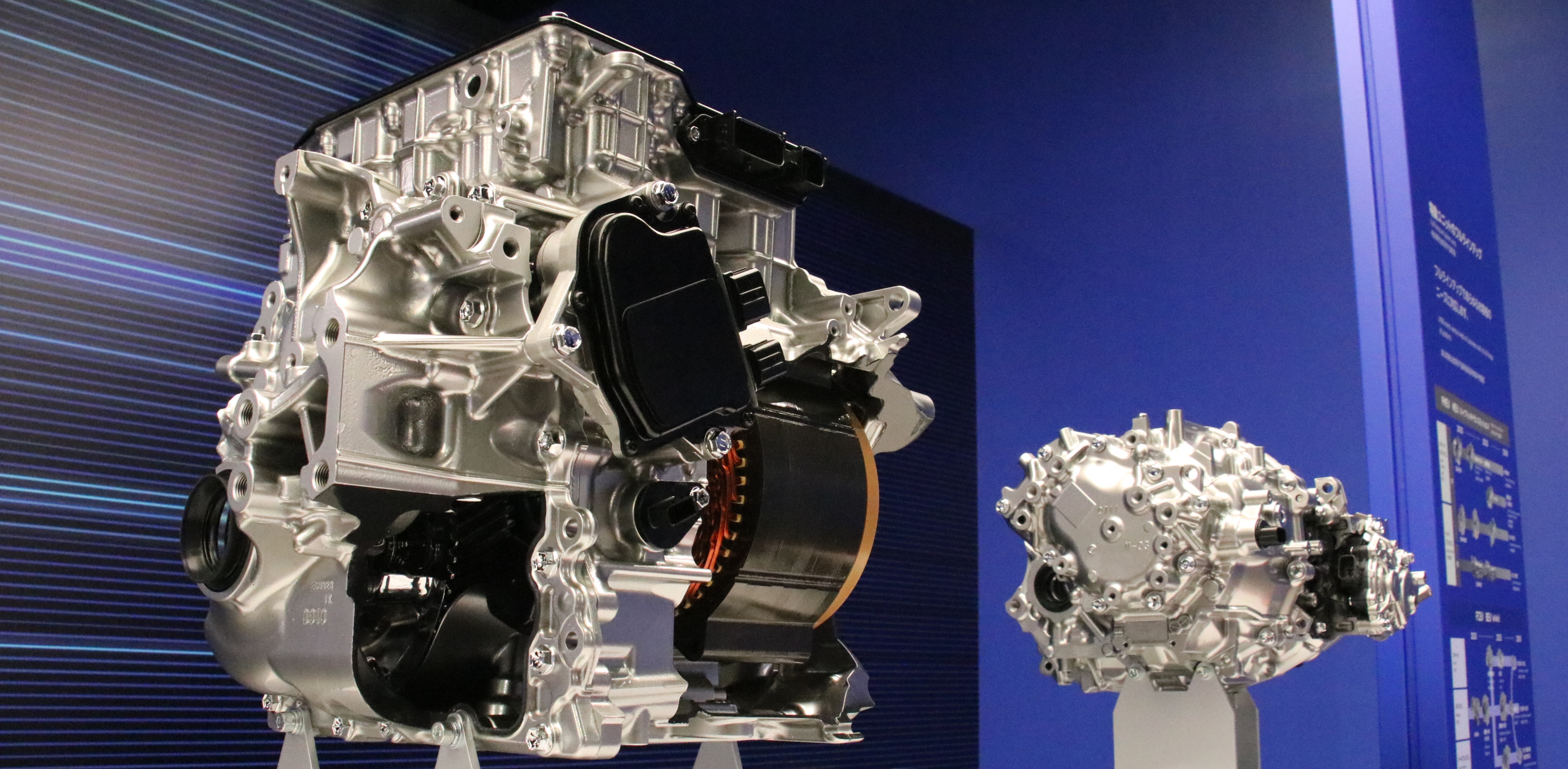

Aisin provides Toyota with gas-liquid separators and FC stack cases as the key components of FCEVs.

A gas-liquid separator is a device to separate the water particles produced by the chemical reaction between hydrogen and oxygen from the circulating hydrogen gas to recover them. The hydrogen gas is recirculated for power generation after the separation of water particles. The gas-liquid separator collects water particles by swirling the circulating gas inside to exert an inertial force on them, thereby achieving a separation rate of 90% or more. The collected water can be discharged from the circulation system to the outside throughthe discharge valve, which is a unique system developed by Aisin.

An FC stack case is a component to hold a stack of several hundred fuel cells together with high precision by applying a load of five tons or more. It is essential to ensuring the power generation performance of each fuel cell. High strength and miniaturization achieved by joining Aisin’s highly specialized large aluminum castings directly improves vehicle mountability of the component and the increases the expansion of FC systems.

Gas-liquid separator (left) and stack case (right) used in Toyota MIRAI

Gas-liquid separator used in Toyota FC module (left)

Gas-liquid separator used in Toyota Industries FC forklift (right)

Air valve module used in Toyota MIRAI (first generation) and SORA (left)

Exhaust drain valve used in Toyota MIRAI (first generation), Toyota Industries FC forklift (first generation), and SORA (center)

Air pressure regulating valve used in Toyota Industries FC forklift (first generation) (right)

Application of automobile technology to household fuel cells

ENE-FARM is a household fuel cell cogeneration system that generates electricity using hydrogen extracted from city gas and uses waste heat from the power generation process to supply hot water and provide space heating. This system is attracting attention as a next-generation environmentally friendly energy source.

The latest ENE-FARM type S 2020 model has a 20% smaller installation area than that of the previous model and the world's highest level*1 of power generation efficiency at 55%.

*1: Among household fuel cell cogeneration systems with a rated output of 1 kW or less (as of February 21, 2022, researched by Aisin)

Click here for more information about ENE-FARM.

Energy Solutions | AISIN CORPORATION Global Website

Infrastructure development is essential for realizing a decarbonized and recycling-oriented society

Aisin is working to promote the use of clean energy through infrastructure development in addition to product development. In March 2021, Konan Kogyo, one of the Aisin group companies, opened “Konan Hydrogen Station Kariya” (Kariya City, Aichi Prefecture).

In addition, Aisin operates the fuel cell bus "SORA" as a commuter bus for employees. SORA is characterized by its excellent environmental friendliness due to no emission of CO2 and substances of environmental concern while driving, as well as its comfortable ride with little noise and vibration.

Konan Hydrogen Station Kariya (left) and fuel cell bus "SORA" for employee commuting (right)

Innovation for better future

Aisin has a history of constantly taking on challenges for innovation. This history has served as the backbone for Aisin in accumulating technologies that enable the company to meet needs for a wide variety of eco-friendly vehicles, such as hybrid vehicles, electric vehicles, and fuel cell vehicles. Aisin’s unparalleled commitment to quality and high manufacturing capabilities that enable stable production of high-quality products are also its strengths.

Japan is leading the world in promoting initiatives to implement hydrogen in society. In order to achieve the goal of a carbon-neutral society, Aisin will further refine its technologies and continue to combine the strength of group companies.